jaw rock crushers diagrams ndash

Jaw crusher PPT - SlideShare

2014年12月9日 A jaw crusher uses compressive force for breaking rocks into smaller pieces by placing the rock between two surfaces, one of which moves back and forth relative to the other to crush the rock. Jaw crushers produce

More

Kue Ken Jaw Crusher Manual - All PDF - Scribd

Kue Ken Jaw Crusher Manual Table of Contents - Rev. 1 Section 1 Safety Section 2 Kue-Ken Jaw Crusher General Information Output Rates Section 3 installation Section 4 Field

More

“Computer Aided Design of Jaw crusher” - 911 Metallurgist

Jaw crushers are used as primary crushers in a mine or ore processing plant or the first step in the process of reducing rock. They follow “crush using compression” mechanism.

More

Jaw Crusher Diagram: Simplified Guide - JXSC

2024年2月18日 Let’s delve into the jaw crusher diagram—a revealing illustration showcasing the trajectory of the movable jaw plate. In action, this plate swings on the eccentric shaft, applying a forceful compression to the material

More

2: Schematic illustration of a jaw crusher by J. Quist.

Download scientific diagram 2: Schematic illustration of a jaw crusher by J. Quist. from publication: Efficient Modeling and Control of Crushing Processes in Minerals Processing Modeling...

More

Jaw crusher in AutoCAD Download CAD free (238.73

Download CAD block in DWG. The file contains a rendering of a jaw crusher, fully rendered in two dimensions. (238.73 KB)

More

Design and Construction of Rock Crushing Machine from Locally

The jaw crusher is a rocks or lumps reduction machine that employs two hardened manganese steel jaws, with one in relative motion against the other which is stationary while the

More

Diagram Jaw Crusher Crusher Mills, Cone Crusher, Jaw Crushers

tech diagram single jaw rock crusher. tm 5-3820-233-12/1 operator and organizational *tm 5-3820-233-12/1 technical manual headquarters 1-1 jaw crusher plant, left side 1-3 wiring diagram ...

More

jaw rock crushers diagrams

jaw rock crushers diagrams 2020-02-19T13:02:11+00:00 Home made jaw rock crusher YouTube. Jun 28, 2016 Gold Mining Hammer Mill Crusher, Crushing Gold Ore To Fine Dust For Precious Metal Recovery MBMM Duration: 6:50 mbmmllc 526,884 viewsSandvik QJ341 mobile jaw crusher features a 1,200 x 750mm ...

More

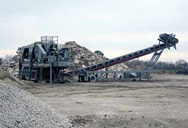

Sandvik QJ341 Mobile Jaw Crusher – World Leading

Sandvik QJ341 mobile jaw crusher features a 1,200 x 750mm (47 x 29 in.) jaw opening, built to tackle the most difficult applications with ease. It has been designed to meet the needs of the operator seeking a high performance

More

Jaw Crusher - Eastman Rock Crusher

Jaw crusher is a compression style rock crusher, useful in crushing the medium-hard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit. Applications mining, quarry, construction waste recycling, aggregate making, etc. Materials Limestone, cobblestone, cobblestone, quartz, basalt, iron ore, granite, shale, sandstone,

More

Stationary jaw crushers - Sandvik jaw crushers - SRP

Browse Sandvik's stationary jaw crushers, designed for high-capacity crushing in demanding conditions. Ideal for mining, quarrying, and recycling applications. Jump to content. ... The optimal jaw plate selection can be determined based on the rock/ore type characteristics (WI, AI) and the feed characteristics (friction, gradation).

More

What Is A Jaw Crusher - MEKA

WHAT ARE THE DIFFERENT TYPES OF JAW CRUSHER? / JAW CRUSHER TYPES. There are two main groups of jaw crushers, categorized according to their jaw movement mechanism. - Single-toggle jaw crushers - Double-toggle jaw crushers. In single-toggle jaw crushers, the movable jaw is supported by the bearing on an eccentric shaft driven by the pitman to ...

More

What Are Jaw Crushers and How Do They Work? - Oreflow

There are several other jaw crushers like bulldog jaw crushers and force feed jaw crushers. But for reference, we’ll focus on the two most widely-used jaw crushers in the mining industry. Down below we’ll discuss how these pieces of equipment operate and what makes them different from each other. Single-toggle jaw crushers

More

“Computer Aided Design of Jaw crusher” - 911 Metallurgist

opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square. Generally primary jaw crushers have the square opening design, and secondary jaw crushers have rectangular opening design. Jaw crushers are used as primary crushers in a mine or ore processing plant or the first step in the process of reducing rock.

More

Types of Crushers: What You Need to Know Machinery Partner

The demand for large-mouthed jaw crushers skyrocketed as the industry began to understand their potential as primary crushers in rock quarries. Through Thomas A. Edison’s research and development, giant machines were innovated and placed around the United States. Smaller-sized jaw crushers were also developed as secondary and tertiary crushers.

More

Types of Rock Crushers Quarry Crushing Equipment Kemper

Jaw Crushers. In compression crushing, jaw crushers tend to be more of a blunt instrument compared to cone crushers, which is why they’re often used in the primary rock crushing circuit stage. Jaw crushers are also known as “rock breakers” and are used to break up larger, harder materials into more manageable pieces.

More

Used Jaw Crushers for Sale - Surplus Record

Reconditioned model 160 Kue Ken jaw crusher with spare parts, - 42 x 48 inch feed opening, - Production: 300 - 700 standard tons/hour (200 - 600 metric tons/hour), - Closed side settings: ... Jaw Rock Crusher, 90 TPH, 800 hours,

More

Schematic diagram of a rock crusher: 1 -Blake jaw

Download scientific diagram Schematic diagram of a rock crusher: 1 -Blake jaw crusher, 2 -rock conveyor, 3 -hydraulic boom manipulator Figure 2 shows a schematic diagram of the solution for ...

More

Jaw Crushers - McLanahan

The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a double-toggle Jaw Crusher. ... The Jaw Crusher is well suited for a variety of applications, including rock quarries, sand and gravel, mining, construction

More

BICO CHIPMUNK JAW CRUSHER - TYPE WD

Bico, Inc. 3116 Valhalla Drive, Burbank, CA 91505 Tel. (818) 842-7179 – Fax (818) 842-7976 sales@bicoinc MAINTENANCE It is of the greatest importance that the crusher is kept properly lubricated at all times (use

More

Pioneer® Jaw Crushers - Astec

The Pioneer ® Series of jaw crushers represents the very latest in jaw crusher technology.. Engineered to be the highest-capacity jaw crusher on the market, the Pioneer ® Jaw Crusher will deliver up to 25 percent more tons per hour than comparable jaw crushers. Pair that with heavy-duty flywheels for reduced horsepower requirements and class-leading stroke for higher

More

Jaw Crushers For Sale - Ritchie Bros. Auctioneers

2018 US EPA Label • CARB Compliant • Scana JY9XL09.3DAA 6 Cylinder 9.3 L Diesel Engine • Requires Diesel Exhaust Fluid • 8 ft x 1 ft Vibratory Grizzly Feeder TEREX 0P0341 44 in x 26 in Jaw Crusher • 40 in Wide Under Crusher Conveyor • 25 in Wide Left Discharge Conveyor • 40 in Wide End Discharge Conveyor • Terex 40 in x 7 ft Cross Belt Magnet • Cable Remote Control

More

IROCK Crushers TJ-2745 – Mobile Jaw Crusher

TJ-2745 – Mobile Jaw Crusher. The rugged and versatile TJ-2745 high capacity, mobile Jaw Crusher offers field-tested reliability for the toughest projects. Optimized for Type 1 crushing applications, this tracked unit features a heavy-duty bofar design and pan feeder chutes with steep angles to reduce material sticking.

More

How Does a Jaw Crusher Work - Kemper Equipment

If you are a rock, sand, gravel, or mineral processing industry veteran or an avid reader of our blog, you know that there are several different types and styles of crushing equipment.The exact crushers you need—jaw, cone, impact, or gyratory—will depend on your site, the product you’re making, and how much you need to produce.

More

Jaw Crushers – MEKA

Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaw; ... For this reason, the crushed rock produced by the jaw crusher is unsuitable as an aggregate in concrete, especially in the construction sector.

More

Gyratory VS Jaw Crushers: Advantages Disadvantages

2016年2月28日 Necessary safety guards are less extensive than for the jaw crusher. Features of the Jaw Crusher. Large receiving opening per dollar of investment. Shape of receiving opening favourable for blocky feed. This, plus point 1, give the jaw a definite advantage over the gyratory, except in the very large sizes, for handling rock of massive formation ...

MoreArticle aléatoire

- agrégat de pierre cos Tin nigeria plan de carrière de pierre Tindia

- produit végétal de concasseur de pierres

- broyeurs la structure

- procédé de meulage arrière

- un impact dépliant concasseur

- flottation de minerai d oxyde de cuivre

- pierre de rivière concasseur prix de la machine

- portant sur chevalets

- vente de concasseur myan à brisbane

- sujets de concasseurs mobiles

- chine fabricant de lusine concasseur

- bloc concasseur à vendre en afrique du sud

- pemecah mesin pengertian concasseur

- Vente Chaude Pe Concasseur à Mâchoires

- pierre en pierre de l'usine de recyclage de concasseur

- concasseur machine uae

- comandclem les nouvelles de la liberation

- concasseur à percussion de scories

- cout de lequipement de depistage de gravier

- équipement de séparation de minerai d enrichissement

- concasseur en machine

- Concasseur à mâchoires automobile

- utilisé concasseur à mâchoires portable australie

- calcul du rayon du convoyeur à courroie

- travail de convoyr à bande

- graphique du prix du minerai de fer par tonne Microsoft

- machine de melangeur de sable maille 1020 kg

- vibrations tamis agitateur équipements de concassage

- machine de concassage de contre attaque de champ de pierre

- équipement de traitement de minerai d or à petite échelle en afrique du sud

- plan d affaires concasseur de carrière de granit en italie

- exploitation minière de concasseurs hydrauliques

- concasseur mobile en namibie charbon de russie

- données de production de concasseur canica vsi

- petit equipement minier concasseur à pierre

- vsi concasseur principe de fonctionnement nigeria

- Usine de concasseur de pierres de 100 tonnes

- Comment Vendre Concasseur A Machoires