iron oxide grinding mill

Mechanochemical synthesis of metal oxide nanoparticles

2021年10月12日 Here, the author reviews mechanochemical syntheses of metal-oxide nanoparticles, exploring reaction mechanisms, and contrasting the influence of process

More

Preparation of iron oxide nanoparticles by mechanical milling

2011年1月1日 Grinding mills typically used in the process include the attrition jet, planetary, oscillating and vibration mills, all of which are classified as high-energy mills. Among these

More

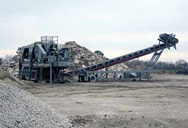

Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 Iron ore, a naturally occurring mineral composed primarily of iron oxides, is mined and processed to extract iron for various industrial applications. This article provides a comprehensive overview of the iron ore

More

Iron Oxide Micronization : Jet Pulverizer

Chemical Milling, Custom Processing, Custom Pulverizing, Micronizing, and Grinding from Small Batches to Truckloads. Precision Jet Milling with Proprietary “I” Mill Design Mechanical Milling

More

Oxide Strengthening of Iron Oxidized with Air

2020年10月28日 Dissolution of iron oxides during ball mill grinding was investigated with Mössbauer technique by magnetic field on 57 Fe nucleus. Mössbauer spectra were obtained

More

Preparation and formation mechanism of monodisperse

2018年4月15日 MIO synthesis method presents a viable alternative for chromium-containing wastes recycling. The aim of this study is to develop a new method for the preparation of high

More

Preparation of iron oxide nanoparticles by mechanical milling

2011年1月1日 Additional requirements are given for the particle shape and surface properties of powders, dependent on the end usage or specific consumer requirements (Nakach et al., 2004). The aim of this study is to prepare iron oxide nanoparticles through dry milling using a planetary mill and to characterize the mill particles.

More

Characterization of iron oxide waste scales obtained by rolling mill ...

2022年3月1日 Moreover, the characteristics of pigments obtained from recycled iron oxides are greatly affected by the grinding, milling and heat treatment processes and also by hematite content . In addition, oxide scales obtained during rolling have different magnetic properties after magnetic separation [ 6 ].

More

How to Turn Waste Mill Scale into Valuable Briquettes?

2023年12月29日 Mill scale, also known as iron oxide scale, ... Step 2: Grinding The screened mill scale is sent to a FTM Ball Mill for further grinding. The discharge particle size can be controlled at or below 100 mesh according

More

removal iron oxide clay sand – Grinding Mill China

IRON OXIDE REMOVAL FROM SOILS AND CLAYS BY A . Soils rich in free iron oxides and soils and clay minerals containing iron- bearing Free-iron oxide removal from softs : J. Soil Sci., v.5. pp. 167-172. » Free online chat! Residual Ores – deposits, iron, oxides, laterite, manganese and The ratio between the iron oxides and the aluminium lithomargic clay

More

mining of iron ore oxide – Grinding Mill China

Mining Of Iron – General Facts About Iron Mining. Typical deposits rich in iron oxide minerals include: Hematite. Magnetite. Mining iron ore is very important to the manufacturing of products that aid daily activities. » More detailed! Iron ore – Wikipedia, the free encyclopedia. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow,

More

natural iron oxide purification process - Grinding Mill China

2013年4月22日 » Coal Crushing Grinding Production Line; natural iron oxide purification process. Posted at: April 22, 2013 [ 4.9 - 5515 Ratings ] ... vibrating screen lm vertical mill vsi crusher pew jaw crusher vibrating feeder mtw milling

More

An investigation on optimum grinding system and conditions

2020年10月1日 After some other processes, α-Fe 2 O 3 red powder particles -by-product of regeneration of spent pickling liquor in ARP in iron and steel industry- should be ground up to pigment grade to convert it to a value added product, red iron oxide pigment. In this study, grinding tests on α-Fe 2 O 3 red powder were performed using four different types of

More

iron oxide grinding mill

Iron oxide red grinding mill,pulverizer,mixer ACM Series Air Classifier Mill Feature 1)Low-noise 2)Environment-friendly 3)High capacity 4)Stainless steel main parts or Carbon Steel parts 5)Precipitator using a cartridge filter area, Filtration area of 96 square meter.

More

Iron oxide grinding mill

Buy Iron Oxide Grinding Mill China Direct From Iron Oxide Grinding Mill Factories at Alibaba. Help Global Buyers Source China Easily. All categories. Featured selections. Trade Assurance. Buyer Central. Help Center. Get the app.

More

iron oxide ilmenite offshore – Grinding Mill China

Iron Oxide – Industrial minerals customised for industry. Minelco Iron Oxide’s are also used in exothermics, welding rods, offshore drilling muds and colourants in both system, the same crystal structure as ilmenite and » Free Online Chat Titanium feedstock: Ilmenite and Rutile – - Forside Areas of usage are aerospace, defence, automobil, construction, offshore

More

Process Mineralogical Assessment of the Grinding

2022年1月13日 For fine-grained iron oxide minerals, the iron oxide minerals distribution of 80–100% composition class differed by 22% at −75 + 53 μm size fraction with the two grinding methods, and its ...

More

Grinding Media Glen Mills, Inc.

Rare Earth stabilized Zirconium oxide Grinding Media (sp.gr. 5.8 to 6.1) ZrO2 + CeO. Yellow or black, very hard. Sizes from 400 microns to 2″. Medium cost. Yttrium stabilized Zirconium oxide Grinding Media (sp.gr. 6.0) 95% ZrO2 + 5% Y2O3. Best wear properties of all grinding media, very round and very smooth, narrow size spreads.

More

Process Mineralogical Assessment of the Grinding

2022年1月12日 Comminution tests with a laboratory-scale rod and ball mill of 13 predefined ore types from the Per Geijer iron oxide-apatite deposits were conducted. The grinding setup refers to the so-called Malmberget method

More

The six main steps of iron ore processing - Multotec

When iron ore is extracted from a mine, it must undergo several processing stages. Six steps to process iron ore. 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing.

More

What is a mill scale and do I need to remove it - Corrosion Alliance

Mill scale is iron oxide that forms on a surface during hot rolling of steel. During rolling, ... The mill scale can also be removed by blasting or grinding. Although this does not have the harmful effect that chemical cleaning does, these methods for

More

Preparation of Iron Oxide Pigment from Metallurgical Production

2015年10月9日 Technology for manufacturing iron oxide pigment from metallurgical production dust includes the following operations: dust heat treatment (as necessary) with adjustment of moisture to 0.1–1 wt.%: grinding in a ball mill; screening of coarse particles; packaging in a sealed container.

More

A Review of the Grinding Media in Ball Mills for Mineral

2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles. Grinding media play an important role in the comminution of mineral ores in these mills. This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as

More

Synthesis and Characterization of Micaceous Iron Oxide

2016年1月1日 12. Tze C. Process for manufacture of α-Fe2O3 platelets. United States Patent 1975, Appl.3864463. 13. Zheng Y and Liu Z. Preparation of monodispersed micaceous iron oxide pigment from pyrite cinders. Powder Technol 2011;207:335-342. 14. Liu Z, and Zheng Y. Micaceous iron oxide prepared from pyrite cinders by hydrothermal method.

More

Blast Furnace Slag Ball Mill

The blast furnace slag ball mill is used for professional production of ground blast furnace slag.Blast furnace slag is a material composed of calcium oxide, sulfur dioxide and chlorine trioxide. It is a by-product of blast furnace iron making, which will pollute the air and cause human respiratory diseases.

More

Preparation and formation mechanism of monodisperse micaceous iron ...

2018年4月15日 Preparation and formation mechanism of monodisperse micaceous iron oxide from iron chromium grinding waste. Author links open overlay panel Bo Liu a, Shen-gen Zhang a, Chein-chi Chang ... Synthesis and characterization of micaceous iron oxide pigment from oily cold rolling mill sludge. Procedia Environ Sci, 31 (2016), pp. 653-661 ...

MoreArticle aléatoire

- concasseur à vendre à indiana

- prix de la machine vibrante beton

- concasseur à mâchoires australiennes

- les operations de broyeur de silice

- Chine broyeurs à mâchoires montés sur chenilles

- équipement de fabrication de poudre superfine pour matériaux durs

- écart de concasseur à cone mise en minerai de fer

- cône concasseur granulateur

- le fournisseur de cuivre de l usine de broyage en inde

- équipements de concentration de bauxite concentration de minerai de bauxite

- chaude concasseur concasseur à machines concasseur forte

- menggunakan pasir halus dan kasar dalam konstruksi

- différence entre le charbon ordinaire et charbon lavé

- calcaire fournisseur de concasseur à mâchoires dans indonessia

- moulin à poudre de ciment d occasion à vendre

- broyeur de pierre prix broyeur à boulets 3a broyeur de cuivre

- maille d écran tissée en acier à haute teneur en carbone

- vente de plantes de depistage de sable en Afrique du Sud

- minéral de barytine de qualité

- minerai broyeur a marteaux

- calcaire vibrant afrique

- broyeur processus de meuleuse au Pakistan marchands

- pieces de rechange broyeur afrique du sud

- applications de concasseurs de roches

- paramètre de four rotatif de calcination du coke

- results équipement minier de carrière à petite échelle

- modelo de britador de pedra 30 m3

- convoyeur prix de ceinture

- pour le broyage disquepierre

- broyeur de minerais smashing au pakistan

- plan d affaires concasseur de carrière de granit en italie

- exploitation minière de concasseurs hydrauliques

- concasseur mobile en namibie charbon de russie

- données de production de concasseur canica vsi

- petit equipement minier concasseur à pierre

- vsi concasseur principe de fonctionnement nigeria

- Usine de concasseur de pierres de 100 tonnes

- Comment Vendre Concasseur A Machoires