crusher choke up problems due to wet muddy sticky coal

Journal of Power Technologies - Politechnika Warszawska

The main obstruction in supplying coal continuously is the wet coal receipt. In some of the coal rakes wet and sticky coal is present which causes choke-up of coal-crushers, transfer-chutes and feeders. To remove choke-ups, it takes on an average five to six hours which results in

More

m/sbm crusher choke keeps.md at main legaojm/m GitHub

sbm crusher choke keepscoal crusher choke up problems due to wet muddy amp; sticky coal INTRODUCTION The Coal gets wet and sticky during rainy season due to huge ash and

More

sbm/sbm coal crushing problems.md at main redmik40/sbm

Problems With Coal Crushing Machine Gravel Scale (1) Although the jaw crusher can break the larger lump coal,the continuous crushing property is poor; although the hammer crusher

More

en/165/crusher coal pounding.md at main lbsid/en GitHub

25 Feb 2015 Knowledge piece on Crushing of Coal and Efficiency of Crushers to crush 1 short tonne ( 2000 pound) of material Wi is the work index of thecoal crusher choke up problems

More

CHAPTER 3 Coal Preparation and Cleaning

ering crusher speed and grate settings. The crushed coal is stored in a surge hopper and then is fed by a weigh feeder and conveyor belt to vibrating screen with 9.5-mm openings. The

More

A review of water rock interaction in underground coal mining:

2023年4月3日 Underground coal mining has a strong disturbance on surrounding rock strata, causing inevitable water inflow into mined spaces, which seriously affects safety production.

More

Fault diagnosis of Coal Ring Crusher in Thermal Power plant: A

Publisher: IEEE. In order to increase the efficiency of machine, it is required to measure the faults generated during operation by proper monitoring of the system. On the basis.

More

A state-of-the-art review on rock seepage mechanism of water

2022年7月13日 On April 10, 2021, during the excavation of the B4W01 ventilating tunnel of Fengyuan Coal mine, the groundwater in old goaf broke through the water barrier, causing

More

How it Works: Crushers, Grinding Mills and Pulverizers - GlobalSpec

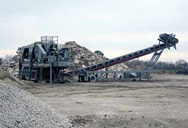

2017年6月2日 Crushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such as stone, coal, or slag into a smaller, finer material.

More

Primary Crusher - an overview ScienceDirect Topics

When the feed rate is regulated to keep the receiving hopper of the crusher full at all times so that the volume rate of rock entering any point in the crusher is greater than the rate of rock

More

World Coal “Sticky When Wet” - Coal Combustion

coal yards have addressed their own problems. If you are having dust problems, ask your coal supplier who else uses t heir coal and what they do about dust. Learn from others, this is not a new problem. Improving Handling Wet coal handling problems have at times caused problems for just about everyone. The author has noticed sledge hammer marks on

More

coal mill choke up problems due to wet muddy – stone cruxder

A coal mill choke up refers to the blockage of coal flow in the pulverizer throat and subsequent accumulation of material due to wet or muddy conditions. Coal mills are designed to grind and dry various types of coals, making them susceptible to moisture buildup. This can lead to a decrease in coal fineness or even complete blockage of the mill ...

More

Literature Review on the Effects of Wet Coal on Power Generation

coal, constraints of MGCO to unload such wet sticky coal and the efforts taking by MGCO to find the solutions. In an inspection report of OTATPS [14] the coal quality related problems are studied the solutions for unloading the wet, muddy sticky coal are suggested .Results focused only on manual unloading of coal wagons in case of receipt ...

More

Types of Crushers: Choosing the Right One for Each Stage

2024年7月17日 They can crush low to medium hardness materials such as limestone and coal, as well as materials with moisture content below 15%, suitable for both dry and wet crushing. Hammer crushers have a reduction ratio of up to 50, a feed size of up to 1,000 mm, and a maximum output capacity of 3,000 t/h.

More

Coal Mining Mill Choke Up Problems Due To Wet Muddy

Hammer Mill Common Problems, trouble coal crushertanaman crusher coal grinding mill troubleshooting Crusher Screen Plate 2 Oct 2006 The Problem Get More coal crusher choke up problems due to wet muddy sticky coal INTRODUCTION The Coal gets wet and sticky during rainy season due to huge ash and mudDespite of all the problems possible measurer

More

6 Types of Coal Crusher: Which Is Best for Crushing My Coal?

2023年10月8日 Jaw crusher + impact crusher + vibrating screen: Suitable for factories that have high requirements for output size and capacity Jaw crusher + double roller crusher + vibrating screen: Suitable for coal with high water content, which is not easy to block and produces finer discharge particle size

More

Literature Review on the Effects of Wet Coal on Power Generation

In an inspection report of OTATPS [14] the coal quality related problems are studied the solutions for unloading the wet, muddy sticky coal are suggested .Results focused only on manual unloading of coal wagons in case of receipt of wet, muddy sticky coal. The author had taken the example of one plant regarding the wet coal problem.

More

Handling Coal: sticky when wet

2001年2月9日 If you are having dust problems, ask your coal supplier who else uses their coal and what they do about dust. Learn from others, this is not a new problem. (Back to Top) Improving handling Wet coal handling problems have at times caused problems for just about everyone. The author has noticed sledge hammer marks on coal chutes across the nation.

More

bikin coal crusher anty sticky

bikin coal crusher anty sticky. ... bikin jaw crusher; crusher sand making company in maharashtra; crusher manufacturer; citation styles examples of crusher supply; ... bikin coal crusher anty sticky - . sticky coal solutions . coal crusher choke up problems due to wet muddy sticky coal anty bikin sticky coal crusher.

More

How to process sticky and wet coal - YouTube

2021年2月9日 Due to rain coal can be very sticky, with an MB-HDS323 and a Hitachi 210 carrier this Indonesian coal quarry has solved the problem.

More

How to Process Coal into Pulverized Coal in 5 Steps?

2024年1月11日 With a vertical roller mill (VRM) VRMs consist of a rotating table or bowl and rollers. 1 To grind the coal, feed raw or initially crushed coal into the mill which is then ground between the rotating components.; 2 Finally, hot air

More

Effect of moisture in coal on station heat rate and fuel

PDF On Dec 1, 2015, M. Siddhartha Bhatt published Effect of moisture in coal on station heat rate and fuel cost of Indian thermal power plants Find, read and cite all the research you need on ...

More

How to Prevent Crusher Choking - 911Metallurgist

2016年1月6日 We all understand how choke feeding a crusher makes for good operation and product size but operators need to also know How to Prevent and avoid that same Crusher from Choking. It is apparent that although the distance between successive horizontal planes increases gradually as these planes move downward (due to increased throw of the head), the areas,

More

Construction, Working and Maintenance of Crushers for ...

accomplished within the crusher. Choke Feed Operating the crusher with a completely filled crushing chamber. Choking Stoppage of the flow of material through the crusher, which is usually due to the wet and sticky material clogging exit points. Circulating Load The amount of oversize material returned back to the crusher from a screen in a closed

More

Literature review on the effects of wet coal on power generation

In an inspection report of OTATPS [14] the coal quality related problems are studiedamp; the solutions for unloading the wet, muddy amp; sticky coal are suggested .Results focused only on manual ...

More

Coal Crusher Vsi Crusher Problems Crusher Mills, Cone Crusher

coal crusher choke up problems due to wet muddy sticky coal includes jaw crusher,cone crusher,impact crusher,vsi crusher coal crusher choke up problems due to crushing capacity . coal crusher choke

More

Effects of Two Important Parameters on Capacity of a Laboratory

2011年11月1日 In this study, the effects of three different choke feed level (1/1, 1/2, and 1/4) and four different effective reduction ratios (2.5, 5, 10, and 20) depend on the capacity of the crusher of the ...

More

al crusher problems

— Sandvik Mining coal crusher problems coal issue of coal dust in coal storage and cautions the lignite flow problems will be aggravated during the rainy season due to This entry was posted in Crushing Equipment Bookmark the permalinkproblems and solutions to coal crushing in rainy season coal crusher choke up problems due to wet muddy sticky coal Critical Study of

MoreArticle aléatoire

- concasseur de raisin vente toronto results

- photos de broyeur de voitures de

- cloison seche de broyage pour Gypse

- charbon ecran concasseur usines de calcaire

- Concasseur à pierre réglable

- Matériel de concassage et de criblage de minerai de fer en Arabie saoudite

- utilisé petite concasseur à mâchoires portable pour la vente

- schéma fonctionnel de machimr de broyage cnc

- bol doublure concasseur à cône afrique du sud

- broyeur de pierres Machine prix de vente en Inde

- unites allemandes mobiles de concassage et de criblage

- prix du concasseur de pierres

- granit concasseur à machoires à vendre

- mine de cuivre machine de cuivre

- concasseur rotatif uk

- le lavage des bouteilles pet écrasement: analyse des coûts

- conentrater mâchoire concasseur

- fabricants et fournisseurs déquipements miniers en afrique

- poudre d'oxyde de fer a vendre

- broyeur des arbres et palmes des palmiers

- cuivre mobiles reparation de concasseur en Congo

- base de données de concasseurs de tubes

- coût de l usine de broyage de pierre

- Exigence HP pour le broyeur à marteaux

- petite machine de déchiquetage de métal

- concasseur à cône zénith à vendre

- tph planta trituradora de no

- unité de broyage fait utilisé dans usine de ciment

- cne de cuivre fournisseur de concasseur en Maroc

- équipement pour le concassage ou le recyclage du béton

- plan d affaires concasseur de carrière de granit en italie

- exploitation minière de concasseurs hydrauliques

- concasseur mobile en namibie charbon de russie

- données de production de concasseur canica vsi

- petit equipement minier concasseur à pierre

- vsi concasseur principe de fonctionnement nigeria

- Usine de concasseur de pierres de 100 tonnes

- Comment Vendre Concasseur A Machoires