significance of ball mill

Ball Mill - an overview ScienceDirect Topics

A ball mill is a type of grinder used to grind and blend materials, and the ball milling method can be applied in mineral dressing, paints, ceramics etc. The ball milling owns the strengths of

More

What Is The Significance Of Critical Speed Of Ball Mill? 4 Key

High-energy omnidirectional planetary ball mill. The KT-P2000E is a new product derived from the vertical high-energy planetary ball mill with a 360°rotation function. The product not only has the characteristics of the vertical high-energy ball mill, but also has a unique 360°rotation function for the planetary body.

More

Ball Mill Grinding Machines: Working Principle, Types, Parts ...

By understanding these aspects, readers can gain a comprehensive understanding of ball mill technology and its significance in various industrial processes. Ball Mill Working Principle. The working principle of a ball mill is based on the impact and attrition between the balls and the grinding media.

More

The significance of gold mining ball mills in the modern mining ...

The significance of gold mining ball mills in the modern mining industry. Gold mining ball mills are integral equipment used in the gold mining process, designed to grind and crush ore materials. These mills are crucial for the extraction of gold from ore and play a significant role in the production of gold worldwide. 1.

More

The significance of ball mill containers in material processing

2. Construction of Ball Mill Containers: Ball mill containers are typically made from high-quality materials that can withstand the rigorous conditions of the grinding process. Common materials include: - Stainless Steel: For its corrosion resistance and durability, stainless steel is a popular choice for ball mill containers.

More

The Significance of Ball Mill Lining Design

The design of ball mill linings plays a crucial role in optimizing the efficiency and performance of the milling process. The ball mill, a key equipment for grinding materials, operates by rotating a cylinder filled with steel grinding balls. Understanding why ball mill lining design matter is essential for improving overall productivity and minimizing wear []

More

Unveiling the Significance of Ball Mill Lining Design

2024年3月7日 These cylindrical devices are designed to grind or blend materials for further refinement, making them indispensable in countless manufacturing applications. However, beyond the mechanical prowess of the ball mill itself, an often underestimated aspect significantly influences its efficiency and longevity – the design of the ball mill lining ...

More

Ball Mill; Principle, Working, and Construction » Pharmaguddu

2022年10月17日 Produced strong vibration and sound and less in case of rubber ball usage. Can not reduce soft, tacky, and fibers materials; Wear occurs inside the cylinders hence chances of possible contamination are high; Less capacity, do not handle the large quantity. Ball Mill Price. Ball Mill Price in India ranges from 53,000 to 1.20 Lac depends on the size.

More

Marcy ball mill - Liming Heavy Industry

2023年9月15日 The Marcy Ball Mill, an indispensable piece of equipment in the mining and metallurgy industry, has played a pivotal role in ore processing and material grinding for over a century.This article explores the history, design, and significance of the Marcy Ball Mill, shedding light on its enduring relevance in modern industrial applications.

More

The significance of ball mill grinding in creating delicious

2024年3月18日 Ball mill grinding is a critical process in the chocolate production industry. It involves crushing and refining cocoa nibs into chocolate liquor, which is then used as a base for various ...

More

The significance of ball mill containers in material processing

2. Construction of Ball Mill Containers: Ball mill containers are typically made from high-quality materials that can withstand the rigorous conditions of the grinding process. Common materials include: - Stainless Steel: For its corrosion resistance and durability, stainless steel is a popular choice for ball mill containers.

More

Ball Mill: Operating principles, components, Uses,

2022年11月30日 Several types of ball mills exist. They differ to an extent in their operating principle. They also differ in their maximum capacity of the milling vessel, ranging from 0.010 liters for planetary ball mills, mixer mills, or

More

What Is The Significance Of Critical Speed Of Ball Mill? 4 Key

High-energy omnidirectional planetary ball mill. The KT-P2000E is a new product derived from the vertical high-energy planetary ball mill with a 360°rotation function. The product not only has the characteristics of the vertical high-energy ball mill, but also has a unique 360°rotation function for the planetary body.

More

Ball milling : A green technology for the preparation and ...

2019年1月9日 Ball milling is a simple, fast, cost-effective green technology with enormous potential. One of the most interesting applications of this technology in the field of cellulose is the preparation ...

More

Comparative Study on Improving the Ball Mill Process Parameters ...

2021年2月19日 The ball mill process parameters discussed in this study are ball to powder weight ratio, ball mill working capacity and ball mill speed. As Taguchi array, also known as orthogonal array design, adds a new dimension to conventional experimental design, therefore, Orthogonal array (L9) was carefully chosen for experimental design to understand the effects

More

Ball Mill - an overview ScienceDirect Topics

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1–1.5 times the shell diameter (Figure 8.11).The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

More

A Review of the Grinding Media in Ball Mills for Mineral

2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles. Grinding media play an important role in the comminution of mineral ores in these mills. This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as

More

Bond Work Index - an overview ScienceDirect Topics

Berry and Bruce (1966) developed a comparative method of determining the hardness of an ore. The method requires the use of a reference ore of known work index. The reference ore is ground for a certain time (T) in a laboratory tumbling mill and an identical weight of the test ore is then ground for the same time.Since the power input to the mill is constant (P), the energy input

More

Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 Ball mills can grind a wide range of materials, including metals, ceramics, and polymers, and can operate on a variety of scales, from laboratory to industrial (Monov et al. 2013).

More

The significance of ball mill grinding in creating delicious

2024年3月18日 Ball mill grinding is a critical process in the chocolate production industry. It involves crushing and refining cocoa nibs into chocolate liquor, which is then used as a base for various ...

MoreArticle aléatoire

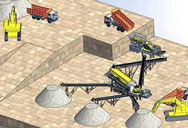

- 20mm40mm amenagement de usine de broyeur de pierres 2

- logiciel de conception de passes de laminoir

- Vsi et machine à laver le sable

- pengecoran moinho de bolas

- unite calcite dolomite de broyage

- broyeur vertical pour le bénéfice de cbmi sciz

- Fournisseurs de machines de broyage de minerai d or en Afrique du Sud

- Fabricants de broyeur à jet d air Mumbai Inde

- le cout de la machine de broyage cryogenique

- pulvérisation de poudre Broyeur à billesuse

- allemands portatifs mobiles concasseur de pierre

- Broyeur à mâchoires cad

- Comptoir de granit concasseurs à machoires Prix

- préchauffeur de concasseur de pierres

- tm rhino modèle de concasseur à machoires pas 1 canada

- concasseur à machoire à machoire à vendre à Uk

- alur proses concasseur

- concasseurs de pierre alimentés

- Danse usine de bo

- crucher de roche pour petite exploitation minière

- gulin concassage moulin de meulage

- La Plus Grande Machine De Terrassement

- concasseur giratoire utilisé broyeur à boulets

- daftar merk concasseur à machoires ex rrc

- concasseurs de carrière portatifs

- le manuel pour le concasseur à cône simons

- or broyeur fait du prix du mexique

- zenit minier et construction

- nous fait petit concasseur de roche fournisseurs

- copeaux de seconde main

- plan d affaires concasseur de carrière de granit en italie

- exploitation minière de concasseurs hydrauliques

- concasseur mobile en namibie charbon de russie

- données de production de concasseur canica vsi

- petit equipement minier concasseur à pierre

- vsi concasseur principe de fonctionnement nigeria

- Usine de concasseur de pierres de 100 tonnes

- Comment Vendre Concasseur A Machoires