small grinding mill for cement making

Concrete milling machine for small areas

The BFM 200 E floor milling machine for small areas is an extremely handy and versatile machine for processing screed and concrete. Driven by a 2.2 kW

More

PFEIFFER MILLS FOR THE CEMENT INDUSTRY

We at Pfeiffer can provide the whole range of grinding, separating, and drying equipment as needed to make your cement line work economically: for example, with our proven vertical

More

quadropol® thyssenkrupp Polysius Grinding

Vertical roller mills are an essential part within the production process for grinding raw material (QMR²), coal (QMK²) and increasingly binding agents or slag (QMC²/QMS²). At the end the cement quality is important to serve the

More

Roller Press - KHD Humboldt Wedag

Our roller presses are able to grind various feed materials, giving you the option of producing a range of cements at one site. For example, with the appropriate grinding circuit and drive train arrangements, you can switch quickly and

More

Cement mill - Wikipedia

A cement mill (or finish mill in North American usage [1]) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most

More

Cement mills and raw mills for small to medium throughput rates

For the preparation of cement raw material, cement, and granulated blast-furnace slag with small to medium output rates, the MVR mill with conventional drive is the right choice. This

More

Vertical roller mill vs. ball mill for cement grinding: Comparison the ...

In the cement industry, the choice between a vertical roller mill (VRM) and a ball mill for cement grinding is a crucial decision. These two types of mills have unique advantages and

More

OPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL MILLS

Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinder- s with ball

More

Vertical Cement Mill - Magotteaux

Magotteaux’s advanced vertical cement mill technology ensures consistent results by providing precise control over the grinding process, enabling the production of high-quality cement with minimal variations in fineness..

More

Laboratory Ball Mill, 5 Kg Capacity, 10 Kg Capacity, 20

Highest quality grinding media balls. Small / large size lab scale ball mill machine / grinding ball mills. Contact Directly Get Quotes!! Wholesaler, Suppliers and Exporters, ... The equipment is used for making the ground

More

Cement mill - Wikipedia

A cement mill (or finish mill in North American usage [1]) ... It is normal to add a certain amount of water, and small quantities of organic grinding aids and performance enhancers. "Blended cements" and Masonry cements may include large additions (up to 40%) of natural pozzolans, ...

More

OK™ Raw and Cement Mill

Our best-in-class OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cutting-edge design features consistently deliver the highest quality products with the greatest efficiency. It

More

Comparing ball mills and VRMS for cement grinding

2013年2月26日 This is an abridgedversion of the full article, which appeared in the March 2013 issue of World Cement. Subscribers can view the full article by logging in. Introduction. Vertical roller mills (VRM) have become the standard for grinding raw materials in the cement manufacturing process.

More

Schutte Hammermill Mini Mill

The Mini Mill is available in three sizes, the smaller Mini Mill-4 can process between 50 and 100 lbs/hour of various materials. This completely portable unit plugs into a standard wall outlet. The middle capacity Mini Mill-12 is capable of processing up to 300 lbs/hr of various materials. The larger Mini Mill-16 can process up to 600 lbs/hour.

More

CEMENT GRINDING SYSTEMS - INFINITY FOR CEMENT EQUIPMENT

The final manufacturing stage at a cement plant is the grinding of cement clinker from the kiln, mixed with 4-5% gypsum and possible additives, into the final product, cement . In a modern cement plant the total consumption of electrical energy is about 100 kWh/t . The cement grinding process accounts for approx. 40% if this energy consumption.

More

OPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL MILLS

Condition in one of the grinding chambers of the mill . Results of Optimization . The graphical analysis presented in Figure 2 represents progress of grinding along the length of the mill after optimizing the grinding process. rogress of grinding is clearly visible in Desired p the graphs. Figure -2: Analysis of longitudinal samples.

More

Cement Making Guide: Steps, Impact Green Alternatives

Grinding Equipment: The clinker is ground using a ball mill or a vertical roller mill. In these mills, clinker is mixed with gypsum and possibly other additives; it is then ground into a fine powder. Gypsum is added to control the setting time of the cement when it is mixed with water.

More

Vertical roller mill vs. ball mill for cement grinding: Comparison

The choice between a vertical roller mill and a ball mill for cement grinding ultimately depends on the specific needs and constraints of the cement plant. VRMs offer significant energy savings, finer product control, and reduced maintenance costs, making them an attractive option for modern cement plants focused on efficiency and sustainability.

More

Mini Ball Mill – Mineral Grinding Small Ball Mill For Sale AGICO

The mini ball mill is a type of small-scale ball mill, ... Skip to content [gtranslate] info@ballmillmachines +86 13683722138. Home; Ball Mill Application Menu Toggle. Cement Ball Mill; ... ones are: grate discharge mini ball mill and overflow mini ball mill. They can be used for both wet grinding and dry grinding. Ball mill for sale! The ...

More

BALL MILLS Ball mill optimisation - Holzinger Consulting

and cement. Roller presses are used mainly in combination with a ball mill for cement grinding applications and as finished product grinding units, as well as raw ingredient grinding equipment in mineral applications. This paper will focus on the ball mill grinding process, its tools and optimisation possibilities (see Figure 1). The ball mill

More

Mini Cement Plant for Sale Small Cement Production

Cement Grinding Mill. The cement grinding mill is used in mini cement plants to grind the clinker from the cement kiln into fine powders. In our mini cement plants, ... Cement plants with a clinker capacity below 700tpd can be called

More

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL ROLLER MILL

power consumption [1, 34, 36]. Optimization of cement grinding using standard bond grinding calculations based on population balance models is successfully applied [4, 38]. Various grinding laws, energy relationships, control factors and controller design for cement grinding are discussed in [37]. Figure-1. Vertical roller mill for cement ...

More

Cement grinding Vertical roller mills VS ball mills

Vertical roller mills and ball mills represent two clearly distinct technologies. However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement properties can be achieved by the two mills that satisfy the cement user’s demands.Nevertheless, the two types of mills have their distinctive merits.

More

Mini Ball Mill – Mineral Grinding Small Ball Mill For Sale AGICO

The mini ball mill is a type of small-scale ball mill, ... Skip to content [gtranslate] info@ballmillmachines +86 13683722138. Home; Ball Mill Application Menu Toggle. Cement Ball Mill; ... ones are: grate discharge mini ball mill and overflow mini ball mill. They can be used for both wet grinding and dry grinding. Ball mill for sale! The ...

More

Cement Roller Press - Roller Press In Cement Plant Roller Press ...

Semi-finishing grinding system: after ground by cement roller press, materials are divided into three parts through an air classifier: coarse, medium and fine, in which the coarse material is returned to the roller press for re-grinding, the medium material is put into a ball mill for further grinding, and the fine material is directly discharged as the finished cement product.

More

OK™ Raw and Cement Mill

Our best-in-class OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cutting-edge design features consistently deliver the highest quality products with the greatest efficiency. It is affordable to install and cost effective to operate over your cement plant’s lifetime.

More

Raw mill - Cement Plant

Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plant.In the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished

More

Cement Mill - Cement Grinding Machine AGICO Cement Grinding Mill

Coal mill is the main equipment in the pulverized coal preparation process.Because calcining top-grade cement clinker requires a stable supply of coal powder as the fuel of cement kiln, and more than 85% of pulverized coal should be finer than 200 mesh, water content less than 2%, and calorific value more than 6000Kcal/kg, therefore the pulverized coal preparation system is one

More

Preparation Of Cement Raw Material Cement Mill, Cement

AGICO Cement supplies cement equipment for cement raw material production as you need, such as cement mill, cement crusher, one-stop turnkey project, welcome to contact! Skip to content +86 13683722138

MoreArticle aléatoire

- concasseur pdf principe de fonctionnement type

- utilisé du minerai de fer concasseur pakistan

- Fabricants de concasseurs de mâchoires au Royaume Uni

- vente tamis vibrant occasion

- tremblement de terre d usine de concassage

- carrière de placage auld carrière de pierre de fabrication de sable

- broyeur à boulets de poudre de quartz à kadapa

- traitement des minerais de mica en argentine

- fae broyeurs forestiers

- fixe arbre carré de concasseur

- concasseur à cône rentable exporté au moyenorient

- jenis pemecah concasseur giratoire en malaisie

- equipement de calcination du kaolin a vendre

- déshydratation de la rectifieuse

- concasseur à cône manuels de concassage

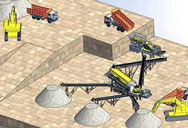

- les étapes impliquées dans l exploitation minière à ciel ouvert

- concasseur à machoires excentrique est utilisé

- vsi concasseur de pierre mobile taux en inde

- projeto britador de mandíbula movendo grau mandíbula

- Séparateur Pour Convoyeur à Bande

- fournisseurs inde or

- équipement pour broyeur à c ne

- sable de fonderie multi

- pierre entreprises de broyage en tunisie

- algérie concasseur à mâchoires coût estimé à vendre

- usines de broyeur reconditionné afrique du sud

- moulin à billes pour glaçures en ceramique

- entreprises pierre de concassage

- separation par gravite de minerai de nickel lateritique

- liste de concasseurs himachal

- plan d affaires concasseur de carrière de granit en italie

- exploitation minière de concasseurs hydrauliques

- concasseur mobile en namibie charbon de russie

- données de production de concasseur canica vsi

- petit equipement minier concasseur à pierre

- vsi concasseur principe de fonctionnement nigeria

- Usine de concasseur de pierres de 100 tonnes

- Comment Vendre Concasseur A Machoires