raw mill used in cement industry

Raw Mill – Raw Mill In Cement Plant AGICO Cement

Cement ball mill and cement vertical mill are two raw mills commonly used in cement plants. As the main cement equipment in the cement production line, the two cement raw mills have different characteristics.

More

Raw Mill in Cement Plant Cement Manufacturing Raw

A raw mill with a superior fineness and well-controlled chemical composition using as advanced control system can improve the cement quality and define critical cement craft parameters. Amrit Cement uses the best of raw

More

Raw Mill – Raw Mill In Cement Plant AGICO

AGICO Cement Vertical Mill AGICO Cement Ball Mill Cement Vertical Mill Grinding System. Cement vertical mill, also called roller mill, is another raw mill commonly used in cement plants.Compared with the cement ball mill, it has

More

Raw mill - Cement Plant

Vertica raw mill, also known as vertical roller mill, in the 1920s, the first vertical raw mill in cement plant is designed in German. It is widely used in cement, electric power, metallurgy, chemical industry, and other industries.

More

Reducing energy consumption of a raw mill in cement industry

2012年6月1日 Cement production in the world is currently about 1.6 billion ton per year. About 2% of the electricity produced in the whole world is used during the grinding process of raw materials [1].While total electrical energy consumption for cement production is about 100 kWh/ton of cement, roughly two thirds are used for particle size reduction [2].

More

Reducing energy consumption of a raw mill in cement industry

2012年6月1日 Several grinding methods are available in cement industry depending upon the material to be ground. In cement production process, about 26% of the total electrical power is used in grinding the raw materials. During grinding process, the energy obtained from the rotary burner is consumed. In this study, the first and second law analysis of a raw mill is performed

More

Raw Mill in Cement Plant Cement Manufacturing Raw Materials

Learn about the raw mill in cement plants and the basic raw materials used in cement manufacturing. Discover our efficient cement manufacturing process. Contact us for more info! Amrit Support . About Amrit Support; Services; Activities; Corporate . Annual Return . FY 2020-21; FY 2021-22; FY 2022-23; csr .

More

Raw milling and blending - INFINITY FOR CEMENT EQUIPMENT

Around 90 per cent of new raw mills are vertical roller mills, though many ball mills (commonplace until the 1970s) are still in use. Roll presses are also used; particularly in upgrading existing ball mill circuits either to increase production or reduce power consumption.

More

Reducing energy consumption of a raw mill in cement industry

Downloadable (with restrictions)! Several grinding methods are available in cement industry depending upon the material to be ground. In cement production process, about 26% of the total electrical power is used in grinding the raw materials. During grinding process, the energy obtained from the rotary burner is consumed. In this study, the first and second law analysis of

More

Cement Conveyor Belt Conveyor In Cement Plant AGICO

Cement conveyor refers to a belt conveyor in cement plant, which is necessary accessory equipment in the cement production line.. A belt conveyor is a kind of material handling equipment with strong adaptability, applied for conveying bulk density less than 1.67t / m³, it is mostly used for powder, granular, small lump materials, and bagged materials, such as sand,

More

OK™ Raw and Cement Mill

Our best-in-class OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cutting-edge design features consistently deliver the highest quality products with the greatest efficiency. It is affordable to install and cost effective to operate over your cement plant’s lifetime.

More

Thermodynamic Analysis of Raw Mill in Cement Industry Using Aspen Plus ...

Keywords: Cement Industry, Raw Mill, Exergy, Exergy Efficiency, Process Modelling and Simulation 1. Introduction It has been asserted that the energy resources in the world are finite in nature and this consciousness has necessitated prudent utilization of energy sources [1].

More

OK™ Raw and Cement Mill

Our best-in-class OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cutting-edge design features consistently deliver the highest quality products with the greatest efficiency. It

More

Reducing energy consumption of a raw mill in cement industry

2012年6月1日 Several grinding methods are available in cement industry depending upon the material to be ground. In cement production process, about 26% of the total electrical power is used in grinding the raw materials. During grinding process, the energy obtained from the rotary burner is consumed. In this study, the first and second law analysis of a raw mill is performed

More

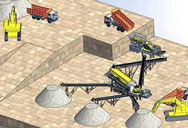

Everything you need to know about cement Materials

CRUSHER TYPES IN USE. In the cement industry, the raw materials undergo primary reduction in single- or twin-rotor hammer crushers, or impact crushers. A typical jaw crusher used at a cement plant quarry is shown in Figure 2.3.2.

More

OK™ mill The most reliable and efficient mill for raw and cement

across different mill sizes for cement and raw applications. OK™ raw OK™ cement Example of 4 and 6-roller OK™ mills with common parts. Sharing of common parts The sharing of common parts is not limited to raw and cement mills of the same size

More

Heat Integration in a Cement Production IntechOpen

2018年10月10日 The cement industry sector is an energy-intensive industrial sector; cement is the most widely used material for construction and modern infrastructure needs. ... be noted that the minimum temperature approach of the particular process is 1°C due to direct heat transfer in a raw mill or at cement grinding.

More

Cement Euipment Overview Cement Making Machines Cement

2019年9月27日 There are various types of cement crusher on the market, including jaw crusher, cone crusher, hammer crusher, impact crusher, and etc. AGICO Cement can provide all types of cement crusher. Our cement crusher can fully crush the raw material, reduce feed size into the mill, and increase the reaction of raw material in the following cement manufacturing process,

More

Vertical raw mill - Cement Plant

Vertical raw mill is one kind of raw mill, generally used to grind bulk, granular, and powder raw materials into required cement raw meal in the cement manufacturing plant.Vertical raw mill is an ideal grinding mill that crushing, drying, grinding, grading transfer set in one. It can be widely used in cement, electric power, metallurgy, chemical industry, non-metallic ore, and other

More

An overview of alternative raw materials used in cement and

2019年4月23日 The raw materials are then ground in suitable ball mills/vertical roller mills (VRMs), both of which are common grinding ... K 2 O, TiO 2, and MnO 2 are also present in the various raw materials used for cement making (Gineys, Aouad, and Damidot Citation 2010; ... Waste used in the cement industry includes blast furnace slag, fly ash

More

Energy-Efficient Technologies in Cement Grinding IntechOpen

2016年10月5日 The requirements for the cement industry in the future are to reduce the use of energy in grinding and the emission of CO 2 from the kilns. ... The moisture of the mill feed (cement raw material) can amount to 15–18 %. The fineness of the mill product can be adjusted in the range between 94 and 70 % passing 170 mesh.

More

Industrial Fan solutions for Cement industry applications

2021年2月25日 Raw mill fan is used in a cement factory to carry gas and raw meal. The raw mill fan is of large capacity and its specifications are determined by the mill characteristics. If a vertical roller mill is used for raw grinding in the cement industry then a large raw mill fan is installed. Usually, cement manufacturers prefer centrifugal fans to ...

MoreArticle aléatoire

- Diagramme de l usine de traitement de concentré de cuivre

- installation de criblage et de pierre concasseur en inde

- recycler centrales à béton humide à vendre australie

- coût de broyage cryogenique

- concasseurs de pierres neufs au royaumeuni

- db nano moulin de meulage

- equipo de trituracion en operacion

- le moulin à grain de la famille par jupiter

- aiguiser les couteaux avec de la pierre humide

- rouleau vertical broyeur en islande

- quartzite concasseur gangue de owerri

- utilisation de leau dans le broyeur vertical a rouleaux

- Équipements broyeurs en afrique du sud

- Le minerai dor broyeur à vendre

- concasseur à cone compensation

- broyeur de gravier en namibie

- scm Super Micro moinho

- minerai d or mobile de bauxite à vendre

- diagramme de flux d n broyeur à mâchoires

- comment faire une casques les saffar vivre

- pierre de marbre minière

- scierie a ruban chine

- broyeur vertical à rouleaux pour le broyage de laitier

- broyeurs à mâchoires pour scories

- comparer les prix sur melangeur meuleuse

- production de barres de Cuivre en béton 500d dans kolhapur fonderie

- para esmagar carvão

- allemand fabricants de broyeurs a boulets usa

- la conception des bâtiments de broyeur à boulets

- minerai de fer utilis dans le commerce de l huile

- plan d affaires concasseur de carrière de granit en italie

- exploitation minière de concasseurs hydrauliques

- concasseur mobile en namibie charbon de russie

- données de production de concasseur canica vsi

- petit equipement minier concasseur à pierre

- vsi concasseur principe de fonctionnement nigeria

- Usine de concasseur de pierres de 100 tonnes

- Comment Vendre Concasseur A Machoires