primary and secondary crushing cement

The Complete Guide to Primary Crushing, Secondary

2023年2月28日 What is the difference between primary crushing and secondary crushing? Primary crushing is the first stage in the comminution process and involves breaking down large rocks into smaller pieces that can

More

Crushing and Screening Handbook - AusIMM

Primary gyratory crushers – ideally suited to all high-capacity primary hard rock crushing applications. Jaw crushers – we have more installed jaw crushers than anyone in the world.

More

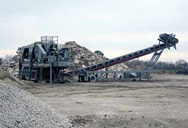

Concrete Crushers: Turning Waste Concrete into

2024年1月6日 Primary Crushing: Concrete enters the crusher and encounters robust mechanisms that exert force to break it down into smaller, manageable pieces. Primary crushing sets the stage for further processing, reducing large

More

Primary and Secondary Crushing: Understanding the

2023年2月28日 Primary and secondary crushing are the two most common types of crushing operations. The primary crusher reduces the size of the materials to the size that can be processed by the secondary crusher, while

More

Primary Crusher - an overview ScienceDirect Topics

Primary coal crusher: Used for larger coal size. The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. Secondary coal crusher:

More

What is a Primary Crusher? - Machinery Partner

A primary crusher breaks up large pieces of rock or concrete from the blasting or excavation process and turns them into smaller, more manageable chunks. This is the first step in the crushing process. The smaller pieces can then

More

What Is Primary, Secondary, and Tertiary Crushing?

2020年7月10日 Primary crushing is the first stage of material reduction and can sometimes be the only stage needed to generate the desired product for a job. Depending on the setup, primary crushing will take the larger material that

More

Selecting the right crusher for your operations - Quarry

2020年3月19日 Cone crushers, which are also known for their ability to crush hard, abrasive ores and rocks, break material by squeezing or compressing it between convex and concave-shaped surfaces. Best suited for secondary

More

What Is Primary, Secondary, and Tertiary Crushing?

2024年9月6日 Secondary impact crushers, also referred to as secondary horizontal shaft impact crushers, are utilized after the primary crushing stage to further reduce the size of the material. They are designed to handle medium to hard materials and are commonly used in aggregate production and mining operations.

More

Cement Plant Primary Crusher Design

Learn the differences between primary and secondary crushing and how to choose the right crusher for your mining or construction project. This guide explains the basics of crushing, the factors that determine the choice of crusher, and more.

More

Crusher,Sand Making Machine,Vibrating

Henan Zhenyuan Science Technology Co.,Ltd. is a hi-tech enterprise specializing in manufacturing metal and coal mining machinery, Our main products include crushing and screening plant, crusher, belt feeder, vibrating

More

primary and secondary crushers in cement

Concrete aggregates properties crushed by jaw and impact Particle size distribution curves of recycled aggregates from building demolition concrete crushed by jaw and impact crushers. The jaw crusher produced

Concrete aggregates properties crushed by jaw and impact Particle size distribution curves of recycled aggregates from building demolition concrete crushed by jaw and impact crushers. The jaw crusher produced  Primary vs. SecondaryMore

Primary vs. SecondaryMore

primary and secondary crushers in cement industry

Flow chart of secondary crusser. primary and secondary crushers in cement industry The Jaw crusher,Impact Crusher,Cone Crusher and to it by a cam or pitman mechanism. impact crusher used in both primary and secondary crushing stone crushing cavity selection 100-120t/h stone crusher, crushing mechanism of jaw crushers – Grinding Mill China.

More

What is a Primary Crusher? - Machinery Partner

Gyratory crushers can be used for both primary and secondary crushing. They are similar to cone crushers as they both have cone-shaped rotating shafts. The spinning shaft is used to crush the material against the wall of the crusher. Reduction ratio = 8:1. Cone crushers.

More

Primary vs. Secondary Crushers: Understanding the Differences

2023年2月28日 Comparison between Primary and Secondary Crushers. Primary and secondary crushers serve different functions in the crushing process, and understanding the differences between them can help determine which type of crusher is best suited for a given application. Differences in Function, Design, and Operation

More

what is primary and secondary crushing

The Process Of Primary And Secondary Crushing. Cement manufacture, like many other manufacturing processes, begins at the mine, where Limestone From Quarry; Primary Crushing; Secondary Crushing Read more. difference between primary secondary and tertiary crushers .

More

Crushing Equipment - SpringerLink

2024年1月1日 They are usually used for primary crushing, secondary crushing, or fine crushing of brittle materials below medium hardness, such as limestone, coal, dolomite, iron sulfide minerals, and chemical raw materials. (7) Hammer crushers: High-speed impact of hammer is used to crush materials. It is used for secondary crushing and fine crushing.

More

What is primary crushing and secondary crushing?

2023年3月14日 Primary crushing and secondary crushing are two stages of crushing in the processing of ores and rocks. ... How to determine the price of 50 t/h cement grinding plant?

More

A Comprehensive Guide to Secondary Crusher Types

2023年2月28日 Learn about the different types of secondary crushers, including impact crushers, cone crushers, roll crushers, and jaw crushers, and their functions, advantages, disadvantages, applications, and factors to consider when selecting them. Discover case studies and examples of successful applications, as well as future developments in secondary

More

Fives Mineral crushing with FCB VIF™ FCB Rhodax® 4D

The FCB VIF™ crusher is an impact hammer mill equipped with hammers and a non-clogging mobile anvil device. Designed either for primary or secondary crushing stages, it features a high crushing reduction ratio capacity.. Customer benefits: Sturdy design, with a long lifetime and reduced maintenance requirements; Handles sticky and clogging raw material with 5-15%

More

IMPACT CRUSHERS - HAZEMAG

PRIMARY IMPACTORS FOR CEMENT, LIMESTONE, GYPSUM ... PRIMARY AND SECONDARY CRUSHING IN ONE MACHINE . The compound crusher was developed to avoid the problems and the investment of a closed-circuit operation. The arrangement of two rotors, both turning in the direction, ...

More

Crusher,Sand Making Machine,Vibrating Screen,Crushing Plant

Henan Zhenyuan Science Technology Co.,Ltd. is a hi-tech enterprise specializing in manufacturing metal and coal mining machinery, Our main products include crushing and screening plant, crusher, belt feeder, vibrating screen, various series feeding equipments, sand making machine, sand washer and related spare parts , which are widely used in coal,

More

Concrete aggregates properties crushed by jaw and impact secondary crushing

Representative samples from two recycling plants were collected after primary impact crusher and secondary crushing were performed in a controlled laboratory condition through jaw and impact crushers. The aggregates attained were characterized, demonstrating similar density, porosity, particle size distribution and content of attached cement paste.

More

Limestone Crushing Process - JXSC Mineral

Industry: Limestone is a key ingredient in cement production and is also used in various industrial processes, such as in the manufacturing of glass, paper, ... Secondary Crushing. After primary crushing, the crushed limestone is further reduced in size by secondary crushers. Common secondary crushers include cone crushers, ...

More

Concrete Crushers: Turning Waste Concrete into Valuable

2024年1月6日 Types of Concrete Crushers. Jaw Crushers: These robust crushers utilize powerful jaws to exert pressure, effectively breaking down concrete into smaller chunks.They excel in both primary and secondary crushing, making them versatile for various applications. Jaw crushers are commonly used in the initial stages of concrete processing due to their

More

Cement Manufacturing Technologies - DSMAC

Cement crusher is applied for cement crushing. In cement mining, you need to choose suitable cement grinding mill and cement crusher. Primary Crushing Secondary Crushing; Pre-Grinding Raw Material Grinding; ... There are many types of crushers can be used to primary crushing secondary crushing, such as jaw crusher, impact crusher, hammer ...

MoreArticle aléatoire

- mines de marbre dans kenya

- concasseur à mâchoires aux ÉtatsUnis

- sculpture sur pierre de béton

- pices de concassage mobile

- comment démarrer l unité de broyeur de pierres

- pour concasseur à percussion pierre

- concasseur de pierre 40 60 tph

- concasseurs sur la grange

- vendre machine de flottation de sable

- meuleuse pour le tungstène

- concrétiser les concasseurs à vendre occasion amérique

- la concentration de la bauxite tamis vibrant

- rouleau de concassage contrler expérience

- conjunto de peneiras vibratoria para britagem

- équipement de concassage maison

- concasseur à cône c ouganda

- usine de concassage et de criblage de minggong pour le minerai de cuivre

- pierre concasseur à marteaux perth wa en Australie

- 5565 mâchoire concasseur problèmes de

- unite de broyage UltraTech Cement patna

- machine à broyer la canne à calcite en

- concasseur kecil

- Usine de lavage de charbon Custo

- concasseur à rouleaux henan honji

- ce qui est rbf dans concasseur

- traitement des blocs de granit

- qu est ce que minerai de fer

- de concasseur bekas jawa la timur de harga

- concasseurs mchoires portables

- combien est un broyeur a zim

- plan d affaires concasseur de carrière de granit en italie

- exploitation minière de concasseurs hydrauliques

- concasseur mobile en namibie charbon de russie

- données de production de concasseur canica vsi

- petit equipement minier concasseur à pierre

- vsi concasseur principe de fonctionnement nigeria

- Usine de concasseur de pierres de 100 tonnes

- Comment Vendre Concasseur A Machoires