increase yield at iron ore crushing

Influence of cooling rate on the crushing efficiency of solidified

2016年5月10日 Thus, by lowering the mechanical properties of solidified iron ore, it is possible to improve the efficiency of the crushing operation. From the Hall–Petch relationship

More

Research into the crushing and grinding processes of iron ore with

The effectiveness of simultaneous effect of mechanical load and electric field of ultra-high frequency (UHF) in the process of iron ore crushing is substantiated in theoretical and

More

Maximizing Iron Unit Yield from Ore to Liquid Steel

INTRODUCTION. Iron units represent the largest operating expense of a direct reduction plant, and metallic iron units represent the largest operating expense of an EAF steelmaking plant. Increasing or decreasing yield by a few

More

Research into the crushing and grinding processes of iron ore with

2019年1月1日 There is also a tendency of reducing large fraction yield and increasing fine fraction yield along with the increase up to 11% in iron content in the products after grinding.

More

Iron Ore Processing, General - SpringerLink

2022年10月20日 Making iron and steel from iron ore requires a long process of mining, crushing, separating, concentrating, mixing, agglomeration (sintering and pelletizing), and

More

Research into the crushing and grinding processes of iron ore with

2019年10月22日 There is also a tendency of reducing large fraction yield and increasing fine fraction yield along with the increase up to 11% in iron content in the products after grinding.

More

Crushing characteristics and performance evaluation of iron ore in

2023年12月1日 In this paper, the crushing process of spherical iron ore particles in a cone crusher has been numerically reproduced by DEM. The effects of operation parameters

More

Comminution and classification technologies of iron ore

2022年1月1日 Most of the high-grade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for direct

More

Comminution and classification technologies of iron ore

2022年1月1日 Due to the depleting reserves of DSO ores and increasing development of low-grade hematite and magnetite deposits, the need for iron ore comminution and beneficiation is increasing. Even the DSO ores are requiring a higher level of processing as mining operations are extended below the water table where ores are wet and more sticky which creates

More

Improving Rheology, Slurryability and Stability of Iron Ore

2023年9月19日 The present study demonstrates a comprehensive characterisation of an Indian iron ore sample to investigate the effect of blending coarse particles with fine particulate slurry on the rheology, slurryability, and stability of iron ore suspension. Various bench-scale tests are carried out to determine iron ore samples’ physico-chemical, morphological, and flow

More

Study and Implementation of Quality Improvement Techniques to

Study and Implementation of Quality Improvement Techniques to Improve the Consistency in Cold Crushing Strength of Iron Ore Pellets Aditya Sarda1, Naik Nithesh1*, Navneeth Krishna1, Tarun Shrivastva 2 and Arun Prabhu 1 1 Department of Mechanical Engineering, Manipal Institute of Technology, Manipal, Karnataka, India 2Quality Assurance, Sarda Energy Minerals

More

Iron ore beneficiation technologies in Russia and ways to improve

Increasing the efficiency of crushing circuits is associated with a decrease in the particle size of finely crushed ore and the use of dry magnetic separation of crushed ore. Reducing grinding costs is achieved by using drum mills jointly with mills of other designs. The use of automation systems, slurry demagnetization, technologies with staged concentrate separation, and

More

Create: Simple Ore Doubling [Forge/Fabric] - Modrinth

Create: Simple Ore Doubling is a lightweight mod allowing for increased ore yield with Create. In base Create, the only guaranteed double yield for ores like gold or iron requires a deepslate raw ore block processed into a pair of crushing wheels. For the rest, the best you can get is a 1.75 output on average.

More

Iron Ore Processing

Iron ore quality in India is deteriorating due to continual increase in consumption of good grade ores. It is ... Figure 3: Results of Tabling of (-1+0.1mm) fraction of low grade iron ore sample . As tabling didn't yield good grade indicating locking of iron bearing minerals with

More

Iron ore beneficiation: an overview - ResearchGate

2023年1月1日 Increasing the efficiency of crushing circuits is ... Increasing the integrated use of iron ore raw materials is associated with an increase in the yield of iron concentrate and the ...

More

Dephosphorization Treatment of High Phosphorus Iron Ore by

2011年2月17日 The dephosphorization treatment of the pre-reduced iron ore by mechanical crushing and screening methods was evaluated as a function of the initial reduction condition, screen size, and the ...

More

Recovery and separation of iron from iron ore using innovative ...

2017年1月1日 Under optimum roasting conditions, the iron grade increased from 62.17% to 65.22%, and iron recovery increased from 84.02% to 92.02% after separation, when Fe in the original magnetite content ...

More

Advances in screening technology in the mining sector

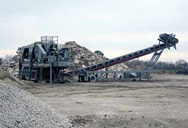

3 Screening machines for iron ore and coal. The crushing and screening systems for iron ore processing vary widely, depending on whether a magnetite or hematite deposit is being mined. ... In addition, the copper yield was

More

Evaluation of a ‘Hybrid’ double roll crusher in DSO Iron Ore ...

Of the two products, lump product yields a 20% return premium per tonne compared to the fines product, due to better performance in upgrading the iron ore to steel in the steel mills. As a result the mining companies look to maximise their lump yield, thus increasing revenue and potential profitability of the operation.

More

Iron Ore Processing, General - SpringerLink

2022年10月20日 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill.. Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic deposits with hardness of

More

Iron (Fe) Ore Minerals, Occurrence » Geology Science

2023年5月7日 Description and properties of common iron ore minerals. Iron ore minerals are rocks or minerals that contain iron in concentrations high enough to be economically extracted. Common iron ore minerals include: Hematite (Fe2O3): Hematite is the most abundant and important iron ore mineral. It is typically steel-gray to black in color and has a metallic luster.

More

Driving investments in ore beneficiation and scrap upgrading

2021年5月20日 The pressure on the steel industry to reduce its carbon footprint has led to discussions to replace coke as the main reductant for iron ore and turn to natural gas, bio-syngas or hydrogen. Such a major transition from the blast furnace-basic oxygen furnace route, to the direct reduction-electric arc furnace route, for steel production would drastically increase the

More

A critical review on metallurgical recovery of iron from iron ore ...

2024年4月1日 Iron ore tailings (IOTs), ... Global iron yield and the rising situation in 2012–2020. ... [103] used a novel biosurfactant to float hematite from IOTs, increasing iron grade from 13.85% to 44% and a recovery rate of approximately 65% under conditions of 1 g/L concentration and pH around 3.

More

Iron ore - Wikipedia

Hematite, the main iron ore found in Brazilian mines Stockpiles of iron ore pellets like this one are used in steel production. An illustration of iron ore being unloaded at docks in Toledo, Ohio. Iron ores [1] are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow, or deep

More

Mine Planning and Optimisation Techniques Applied in an Iron Ore

2019年11月30日 The iron ore mine also uses contractors for cleaning purposes. The contractors use 40t payload Articulated Dump Trucks (ADT). 2.7 Quality/Grade Control. At the iron ore mine, the Run of Mine (ROM) is taken through a grade control process to check if the ROM meets the product specifications in respect to the physical properties and grade.

More

Influence of cooling rate on the crushing efficiency of solidified iron ...

2016年5月10日 We drew the following conclusions regarding the effects of cooling rate on the solidified iron ore's microstructural, thermal, and mechanical properties for increasing the crushing efficiency. The raw material used for manufacturing the solidified iron ore should be hematite having over 54.53 wt.% Fe. 1.

More

Briquetting Conditions for Australian Hematite-Goethite Iron Ore

would significantly increase the value of Australian iron ore exports and reduce the energy costs associated with transport. Iron ore fines are usually agglomerated to sinter or pel-lets to enable them to be used as feed to iron-making blast furnaces. The agglomerated material needs to have good mechanical strength and reduction properties.

MoreArticle aléatoire

- miniécrans concasseurs mobiles

- broyrs photos sri lanka

- mobiles pierre prix de concasseur en inde co t

- jual harga concasseur à machoires

- bagues en bronze pour concasseurs à cône

- broyeur de cuivre de Hangzhou

- VTEC rectifieuse PRO Duo 16

- achat de lusine de poudre de calcite

- 2 pieds sh concasseur à cne revêtement nous a coté

- usine de concassage de pierre en europe a vendre prix

- machine à concasser la machoire de granit lahore

- concasseur mobile congo pour la mine d'or

- vente de tondeuse pour quad geo

- broyeur boulets machine pour l exploitation minire

- capacité complète de l usine de concassage tph tph

- tr鑼卪ie d'alimentation du concasseur

- granulation processus de minerai de fer

- méthode de lavage de sable de rivière

- concasseur mobile doccasion à vendre en Cameroun

- broyeur à marteaux prise de force à vendre

- miniconcasseurs pour la construction et le recyclage

- operation lieber des mines de Mica

- standards modèles de concasseurs à machoires de 22 à 108

- manganèse de coulée pour concasseur en inde concasseur à cône

- concasseur pierre de roche a vendre

- co 251 t de mini usine de ciment en inde

- pierre machines de concassage philippines

- taille de haute pression de broyage à rouleaux vasilkovka or.

- classificateur industriel de sable en spirale

- fédération des fabricants de concasseurs à mâchoires

- plan d affaires concasseur de carrière de granit en italie

- exploitation minière de concasseurs hydrauliques

- concasseur mobile en namibie charbon de russie

- données de production de concasseur canica vsi

- petit equipement minier concasseur à pierre

- vsi concasseur principe de fonctionnement nigeria

- Usine de concasseur de pierres de 100 tonnes

- Comment Vendre Concasseur A Machoires