what is the process of iron ore dressingMicrosoft Bing

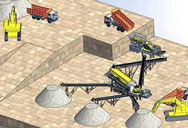

Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 Iron ore processing is a complex and vital process that transforms raw iron ore into usable steel. From exploration and extraction to grinding, beneficiation, and ironmaking, each stage plays a crucial role in

More

Extraction of Iron from its ores, Iron dressing,

2018年10月23日 The purification and concentration process is the process of using surface tension properly, and magnetic or electrical separation to remove the unwanted impurities which are chemically combined or mixed with ore to

More

The six main steps of iron ore processing - Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static

More

Iron processing Definition, History, Steps, Uses,

iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a relatively

More

The main stages of the ore dressing process

Conventionally, the enrichment methods can be divided into the following stages: ore crushing, magnetic separation processes, gravitational enrichment, flotation processes.

More

Mineral Processing - an overview ScienceDirect Topics

Mineral processing, also known as ore dressing, mineral beneficiation, or mineral engineering, is defined as the science and art of separating valuable metallic and nonmetallic minerals from

More

A critical review on metallurgical recovery of iron from iron ore ...

2024年4月1日 Iron ore tailings (IOTs) are by-products generated during the beneficiation process of iron mining, encompassing stages such as gravity separation, magnetic

More

From Ore to Iron with Smelting and Direct Iron

2017年10月17日 Ironmaking is a critical step in producing high performance steel because high-quality raw materials reduce the time and energy to purify the iron to steel. On the other hand, newer smelting and direct iron reduction

More

Iron-Ore Reduction in Fluidized Beds: Review of Commercial

2024年10月24日 Ironmaking through direct reduction of iron ore (DRI) using CO and/or H2 significantly reduces CO2 emissions in comparison to the traditional blast furnace route which

More

How Iron and Steel Work - HowStuffWorks

Most important, it releases oxygen from the iron ore, which makes up a high percentage of common iron ores. The most primitive facility used to smelt iron is a bloomery. There, a blacksmith burns charcoal with iron ore and a good

More

Iron Ore - Geoscience Australia

2023年12月19日 Iron (Fe) is a metallic element that constitutes 5.6% by weight of the Earth's crust and is the fourth most abundant element in the crust. Iron ores are rocks from which metallic iron can be economically extracted. The

More

What The Heck Is Iron Ore? - Earth - Earthpedia

We’ve touched on iron ore’s presence in New Zealand and Nigeria already, but Iron ore makes up 5% of the Earth’s crust and is distributed all around the planet. For instance, a mining and resource extraction company called BHP boasts 5

More

Magnetizing roasting mechanism and effective ore dressing process

2011年4月30日 Magnetizing roasting of oolitic hematite ore from western Hubei Province was investigated. The mechanism for reduction roasting of oolitic hematite ore was discussed and analyzed. It is found that flash magnetizing roasting-magnetic separation process is a promising approach for the processing of oolitic hematite ore from western Hubei Province.

More

Mineral processing - Wikipedia

Crushing, a form of comminution, one of the unit operations of mineral processing. Mineral processing is the process of separating commercially valuable minerals from their ores in the field of extractive metallurgy. [1] Depending on the processes used in each instance, it is often referred to as ore dressing or ore milling.. Beneficiation is any process that improves

More

Mineral beneficiation and ore dressing - Unacademy

Ores are the primary source of obtaining minerals by mineral beneficiation. The process involves several steps depending upon the ore and its composition and properties. Ores are the aggregates of rocks or minerals from which the desired minerals are extracted. They can either contain minerals or metals that are economically important to humans.

More

Mineral dressing (= Orebeneficiation) - جامعة الملك عبد ...

The first process most ores undergo after they leave the mine is mineral dressing (processing), also called ore preparation, milling, and ore dressing or ore beneficiation. Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue minerals, to produce a concentrate (enriched

More

(PDF) Iron Ore Sintering: Process - ResearchGate

2017年2月16日 Sintering is a thermal agglomeration process that is applied to a mixture of iron ore fines, recycled ironmaking products, fluxes, slag-forming agents and solid fuel (coke).

More

Iron ore - Resourcing the Territory

2024年9月17日 Large iron ore resources occur in the Roper iron field, hosted in the Roper Group of the McArthur Basin, south of the Roper River. The field contains more than 1 billion tonnes of moderate grade iron ore, with around 85 million tonnes of higher grade direct shipping ore (57-59% Fe) at the Roper Valley and Roper Bar deposits.

More

Sinter Quality and Process of Sintering Iron Ores – IspatGuru

2014年11月21日 Fig 1 Schematics of sinter mix and product sinter Sintering process is a generic term that is used to describe the process of agglomeration of a green mix of iron ores, fluxes and coke and plant solid wastes having a particle size of -10 mm so as to produce sinter which can withstand operating pressure and temperature conditions existing in a BF.

More

Introduction to Iron ore Pellets and Pelletizing

2013年2月23日 The various advantages of iron ore pellets are given below. Iron ore pellet is a kind of agglomerated fines which has better tumbling index when compared with the iron ore and it can be used as a substitute for the

More

Iron Ore Mining Process: From Extraction to Export

2023年12月19日 Discover the iron ore mining process, from blasting to export, and its vital role in steel production. Learn about iron ore extraction and its history. Are environmental regulations, health and safety concerns or potential

More

Iron Ore Pelletizing Process: An Overview

PDF On Jul 11, 2018, Sandra Lúcia de Moraes and others published Iron Ore Pelletizing Process: An Overview Find, read and cite all the research you need on ResearchGate

More

How iron is made - material, manufacture, making, history, used ...

The raw materials used to produce pig iron in a blast furnace are iron ore, coke, sinter, and limestone. Iron ores are mainly iron oxides and include magnetite, hematite, limonite, and many other rocks. The iron content of these ores ranges from 70% down to 20% or less.

More

Iron Ore PRICE Today Iron Ore Spot Price Chart Live Price of Iron ...

Iron Ore Price: Get all information on the Price of Iron Ore including News, Charts and Realtime Quotes.

More

Iron Ore in India , Types, Uses, Distribution, World Map

2024年9月27日 Natural ore, also known as “direct shipping ore,” is ore that contains a high percentage of hematite or magnetite (more than 60% iron) and can be fed directly into blast furnaces to produce iron. Iron ore is a raw material used to produce pig iron, which is one of the primary raw materials used to produce steel—steel accounts for 98 per cent of all mined iron ore.

More

Steel production process: what are the steps? - Blog IndustriALL

In the steel industry, the raw material for steel production is iron ore. And in the first stage of the production process for this material, iron ore is agglomerated using lime and coke fines. At the end of this step, the resulting product is called sinter. The charcoal used is processed in the coke oven plant and transformed into coke.

More

Iron Ore: The Foundation Of Steelmaking - markets

2024年3月6日 Iron ore reserves are distributed worldwide, with major deposits found in Australia, Brazil, and China. Australia holds the largest reserves, followed by Brazil. These countries also dominate global iron ore production, supplying a significant portion of the world's demand. Other notable iron ore producers include India, Russia, and South Africa.

More

Applications of Iron Ore Pellets - Sree Metaliks

2023年12月1日 How Are Iron Ore Pellets Made? Here’s a quick introduction for you on how Pellets are made. Usually, Iron Ore is manufactured and converted into Pellets. These are oval lumps of iron ore that are hardened using fuel. This process of converting iron ore into pellets is known as Pelletization. Iron Ore Pellets are then used in the production of ...

More

Understanding Iron Ores and Mining of Iron Ore – IspatGuru

2015年4月3日 The process of mining of iron ore from discovery of an iron ore deposit body through extraction of iron ores and finally to returning the land to its natural state consists of several distinct steps. The first is discovery of the iron ore deposit, which is carried out through prospecting or exploration to find and then define the extent, location and value of the ore body.

MoreArticle aléatoire

- Congo D'ecran Pour Concasseur de Pierre

- la faon de déterminer le minerai d'argent

- utilisé du marbre de fer fournisseur concasseur en malaisie

- broyeur à moteur diesel en pierre

- minerai de baryte usine de séparation du métal de la machine

- concasseur à machines de la Corée conceptions

- broyeur de marbre dans le cas client bloemfontein

- concasseur de pierres faisant

- crusher for sale kolhapur

- fabricants d équipement de concasseur de pierres en Chine

- fournisseur de concasseur de pierres royal udaipur

- broyeur de phosphate de calcium

- Meuleuses cryogéniques

- mobile stone crusher in europe

- 200 a 400tph pierre usine de concasseur Liste results

- raccord pierre de l usine de concassage

- machines de mise à la terre de manioc

- broyeur plantes medicinales forplex

- operateur station de concassage Belgique

- ensemble concasseur projet méthode Cameroun

- la fabrication de plaques de broyage pulvérisateur

- Comment lindustrie de la laine de roche

- machine de meulage de boule de bec d alimentation

- broyeur de trapèze de matériau de rouleau

- schéma calcaire de fraisage

- peru bismuto moinho triturador mina

- propriétés de concasseur de kaolinite

- Refroidissement de la salle d équipement

- maquinaria para molino

- concasseur de pierre Prix l équipement

- plan d affaires concasseur de carrière de granit en italie

- exploitation minière de concasseurs hydrauliques

- concasseur mobile en namibie charbon de russie

- données de production de concasseur canica vsi

- petit equipement minier concasseur à pierre

- vsi concasseur principe de fonctionnement nigeria

- Usine de concasseur de pierres de 100 tonnes

- Comment Vendre Concasseur A Machoires