New Aarkay Coal Crusher design

Coal Crusher By New Aarkay Industries - TradeIndia

Buy low price Coal Crusher in Bapunagar, Ahmedabad offered by New Aarkay Industries. Coal Crusher is available with multiple payment options and easy delivery.

More

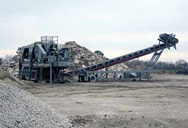

Crushing Plant Design and Layout Considerations - 911 Metallurgist

There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production requirements and design

More

New Aarkay Industries in Ahmedabad, Gujarat, India - Company

New Aarkay Industries - is a leading Manufacturer, Supplier of Coal Handling Plant , Coal Handling Plant, from Ahmedabad, Gujarat, India

More

Mechanical Design and Analysis of Automatic Coal Crushing

A Coal crusher accommodates pummeling of Coal to a yield size of 3" or less. Reusing tasks may extend from basic, physically sustained, independent machines to indulgent pulverizing

More

6 Types of Coal Crusher: Which Is Best for Crushing My

2023年10月8日 This blog outlines 6 types of coal crushers, and their pros and cons, to aid your coal crusher selection.

More

(PDF) Research on Structural Design of Coal Crusher

2020年7月24日 This paper takes the specific characteristics of pulverized coal room in thermal power plant as the starting point,firstly, this paper analyzes the process layout and structure selection, and...

More

New Aarkay Industries - Dial4Trade

Manufacturer,Wholesale Supplier / Wholesaler Manufacturer of Impact Crusher, Seed Processing Machinery, Coal Crusher offered by New Aarkay Industries from Ahmedabad, Gujarat, India -

More

[PDF] Research on Structural Design of Coal Crusher House in

Finally, based on the engineering example, a new structure form of vibration isolation design is creatively proposed, which provides a new design idea for the practical engineering design.

More

Research on Structural Design of Coal Crusher House in Thermal

This paper takes the specific characteristics of pulverized coal room in ther-mal power plant as the starting point, firstly, this paper analyzes the process layout and structure selection, and...

More

Spring Support of Coal Crusher Foundations in Power Plants

Typical Spring Unit for elastic support of a coal crusher. Such an approach usually produces a de-sign with a concrete slab on tall columns, all supported on a heavy base mat. This design

More

Hammer Crusher for Coal [ KURIMOTO, LTD. Indonesia ]

Demonstrates good performance in crushing coal! The Hammer Crusher is an impact crusher designed to repeatedly crush raw material between a beater head rotating at high speeds ... Compact design. Compact design saves space. Applications. Suitable to crush coal ... Crusher, Pulverizer/Mill, Classifiers. New-type Pneumatic Ultra Fine Grinding ...

More

(PDF) Design of Impact stone crusher machine

2019年5月31日 The main objective is to design impact stone crusher. ... performed for over a hundred years in coal breakers, ... Building design and construction handbook 6th ed. New Jersey Columbus: McGraw ...

More

(PDF) 3-D designing of an organic waste crusher

2019年6月11日 M Andrianto proposed an organic waste crusher for garbage with recycling value such as compost, feed pellets, biomass pellets and coal, and performed mechanical design and 3D modeling.

More

Coal Crushers Coal Pulverizers Mills Williams Crusher

Coal is crushed to desired fineness between spheres or cylindrical rollers. After that, air from the boiler is heated to around 330°C (650°F). The raw coal is then fed into the pulverizer where it is ground into fine coal particles. What are the Advantages of Pulverized Coal? Pulverized coal produces a larger amount of heat than traditional coal.

More

Spring Support of Coal Crusher Foundations in Power Plants

of a coal crusher Spring Support of Coal Crusher Foundations in Power Plants Coal crushers of all types, such as ring granulators, pulverizers, hammermills, ro-tary breakers, roll and jaw crushers, can often cause signifi cant and unacceptable vibrations in their supporting structures. The source of the vibration from a pulver-

More

Shandong Bangde Heavy Industry Technology Co., Ltd_jaw crusher,new

Shandong Bangde Heavy Industry Technology Co., Ltd. is a large-scale machinery manufacturing enterprise approved by the relevant state departments and encouraged to invest. The predecessor of the enterprise has experienced 17 years of ups and downs and day and night, and reserves a wealth of production experience, management experience and human resources.

More

Coal Crusher Crushco

We have applied 21 years of Crusher experience to design manufacture a range of robust heavy duty COAL CRUSHERS, suited for the challenging opencast conditions. STANDOUT FEATURES. Efficient crushing sizing Reduced fines production Robust, heavy duty components ... CRUSHCO COAL CRUSHER 900HD

More

Which Equipment Is Best For Crushing Wet Coal - Eastman Rock Crusher

2022年11月9日 1. Wet Coal Jaw crusher: (1) The jaw crusher is a driven extrusion type, which consists of two jaw plates, a movable jaw and a static jaw, forming a crushing cavity. Simulate the movement of two jaws of an animal to complete the material crushing operation; (2) Specifically, the jaw wet coal crusher is suitable for feeding granularity of 1200mm, with a wedge-shaped

More

Crusher Batubara - pt. Penta Inti Persada, Manufaktur Coal

Roll Crushers are simple in design and construction, long lasting, economical, and versatile. Two roll crushing surfaces operate at a fixed distance apart, so product size is much more consistent. Both oversized pieces and fines are minimized. Double roll crushers reduce primarily through compression, although some shear is obtained with toothed rolls.

More

(PDF) A New Model for Comminution Behavior of Different Coals

A New Model for Comminution Behavior of Different Coals in an Impact Crusher . × ... a set of t-curves were calculated from the laboratory impact crusher, and a new model was developed. ... lining design, hammer design, and feed dose of coal in impact crushers, which are widely used in power, cement, and mineral processing plants. For this ...

More

Primary Crusher Selection Design - 911Metallurgist

2015年12月24日 How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not. The crusher

More

mobile crusher in the coal mining - LinkedIn

2023年12月12日 Revolutionizing Coal Mining with SBM's Cutting-Edge Mobile Crusher Technology Introduction: In the ever-evolving landscape of coal mining, the need for efficient and sustainable solutions has ...

More

(PDF) Design of Impact Stone crusher machine - Academia

• Double Roll Crusher • Single-Roll Crusher • Hammer Crusher • Impactor/Impact Breakers • Rotopoctor 2.3 Detail design 3.2 Classification of crusher In the detail design phase the following activities are completed: • Detailed engineering drawings suitable for manufacturing including two and threedimensional drawing using SolidWorks.

More

An Improving Design of Solid Garbage Crusher for Garbage Coal ...

Solid garbage crusher is one of the most important equipments in garbage coal production line. Faults of solid garbage crusher have great influence on the efficiency of garbage coal production line. To solve the problem, an improving design of solid garbage crusher is presented. The key factors that cause the faults to crusher are confirmed through the stress computation of

More

SELECTION OF CRUSHER DESIGN CONCEPTS AS A SUSTAINABLE

This study has selected three can crusher design concepts from previous researchers: motor-operated crusher, mechanical crusher, and pneumatic crusher, as shown in Table- 2. WEIGHTED DECISION MATRIX ANALYSIS This study used the Weighted Decision Matrix to evaluate product sustainability from the selected can crusher design concepts.

More

Coal Crusher Plant - pt. Penta Inti Persada, Manufaktur Coal

DOUBLE ROLL CRUSHER Roll Crusher are simple in design and construction, long lasting, economical, and versatile. Two roll crushing surfaces operate at a fixed distance apart, so product size is much more consistent. Both oversized pieces and fines are minimized.. Double roll crusher reduce primarily through compression, although some shear is obtained with toothed

More

new aarkay coal crusher

Harga Jaw Crusher 20 66 Kw Al Russian. 250 ton hour mobile crusher coal russian version impact crusher for 10 tons of coal hour russia impact crusher ton per hour impact crusher for 10 tons of coal hour russian crusher 10 crusher youtube apr 10 10 12 jaw crusher marshal type per hour 10 mt capacity supplier in chennai 10 x 6 denver roll crusher ...

More

Modern Crusher Plants: Types, Components, and Applications

2024年7月17日 Crusher plants come in various configurations, each designed to handle specific materials and produce desired output sizes. The choice of crusher plant depends on the nature of the material, the required production capacity, and the end-use of the processed material. Jaw Crusher Plants. Jaw crusher plants are widely used in primary crushing ...

More

Aar Kay Spring Industries, New Delhi - Manufacturer of Crusher Springs ...

We Aar Kay Spring Industries, are a well established manufacturer and wholesaler of springs. Available in different specifications, our range includes Helical Springs, Elevator Springs, Stone Crusher Springs, Compression Springs, Tension Springs and Buffer Springs etc.

More

Crusher, Coal mineral sizer - GrabCAD

2014年12月20日 The Computer-Aided Design ("CAD") files and all associated content posted to this website are created, uploaded, managed and owned by third-party users. Each CAD and any associated text, image or data is in no way sponsored by or affiliated with any company, organization or real-world item, product, or good it may purport to portray.

More>> Next:De Chart Minière Concasseur Flux Minière

Article aléatoire

- prix � x 250 concasseur à mâchoires

- broyeur de calcaire mais Belgique

- utilisation de la séparation magnétique

- Dolamite broyeur de pierres en vente Senegal

- britador de intulhos usado a venda sc

- fabricants de concasseurs à mâchoire à SKD en chine

- vibration raymond broyeur

- granit broyeur au Algérie

- n1nfwu concasseur à mâchoire

- fonctions de la machine de broyeur à boulets

- utiliser la roche coût de linstallation de concassage

- combien de temps faut il pour installer un concasseur a cne

- les tamiseurs du sel sch

- pierre écrasant les prix des machines za

- franais gravier broyeur de pierres

- rapport d'un broyeur de pierres de 200 tph de projet

- dot web concasseur clé numarasi

- comment calculer la capacite de la soute a charbon

- anneau concasseur é marteaux

- acheter un moulin à sel de Bed Bath Beyond

- le systeme dalimentation vibro en inde

- nouvelle conception du convoyeur à vis avec calcul

- Concasseur Formulaire

- granules au charbon afrique du sud

- introduction générale de l usine de concassage

- charbon brut concasseur à machoires

- fournisseur de l'usine de broyeur à boulets de baryte en maroc

- broyeur et écran afrique du sud

- ecrasant la machine au Algérie et principe

- équipement utilisé pour le traitement du minerai

- plan d affaires concasseur de carrière de granit en italie

- exploitation minière de concasseurs hydrauliques

- concasseur mobile en namibie charbon de russie

- données de production de concasseur canica vsi

- petit equipement minier concasseur à pierre

- vsi concasseur principe de fonctionnement nigeria

- Usine de concasseur de pierres de 100 tonnes

- Comment Vendre Concasseur A Machoires