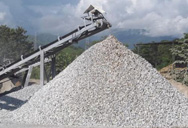

quarry crushing plant and the size

Crushing and Screening Handbook - AusIMM

The plant’s capacity and the size of the feed material are the main factors in selection of a primary crusher. To ensure good performance of the primary plant and prevent production losses, it is necessary to have an adequate cor-relation between the size of the feed material

More

Crushing Plant Design and Layout Considerations

There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production requirements and design

More

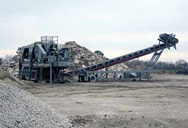

What Is Quarry Crusher - On-site Processing Stone, Rock, Granite

2024年2月22日 Quarry crusher is a piece of equipment that break down natural stone or other solid materials, such as limestone, granite, cobblestone, quartz, and basalt, into sand,

More

Microsoft PowerPoint - Lecture 22, Chapter 14 (AGGREGATE

In operating a quarry and crushing plant, the drilling pattern, the amount of explosives, the size shovel or loader used to load the stone, and the size of the primary crusher should be

More

Selecting the right crusher for your operations - Quarry

2020年3月19日 Best suited for secondary crushing applications, cone crushers are designed to crush pre-sized materials, usually 100mm, 150mm or 200mm, depending on the size of the crusher. Cone crushers can form

More

Types of Rock Crushers Quarry Crushing Equipment

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment

More

Tips for designing an efficient crushing and screening

2013年4月4日 The quarry shot material should be analysed for maximum feed size, gradation, chemical composition, amount of clay, hardness and variations within the deposit or ledges. A list of product sizes needs to be determined as

More

Enhanced Plant Design for Aggregate Processing Agg

2012年10月15日 Plant design, refurbishment or extension is dependent on the intended purposes and outcomes of the plant. Steve Mellor explains why enhanced plant design can, in the long term, be critical to the productivity and

More

Selecting the Right Crusher for Quarry Operations - Agg-Net

2014年9月23日 The number of screens available on a crusher unit will dictate the number of different sized products a machine can produce in one pass. Closed-circuit machines

More

Standard Mineral Processing Plants - Quarry Mining

2020年7月26日 Quarry Mining LLC is the leader in mineral processing. We have many high-capacity plants in operation around the MENA region. Let us plan your next plant. Get in Touch. Stationary secondary standard crushing (Stone

More

Selecting the right crusher for your operations

2020年3月19日 Similarly, three-deck plants are required when production specifications require four different size classifications. MOBILE CRUSHERS Some operations do not require mobility, since the projected life of the quarry

More

Revamp for three-stage hard rock crushing plant

2020年3月19日 The flowsheet for this plant, which has a capacity of 250 tonnes per hour (tph), can be seen in (Figure 3). Depending on the requirements of the producer, the plant can be designed as a stationary plant, a semi-mobile

More

Simplifying the crushing process - Pit Quarry

2019年5月10日 As the first stage in a crushing circuit, primary crushing reduces material to a size and shape that can be handled by a secondary crusher. Typically, the minimum setting on most primary crushers is about 4

More

Crushing Products Size and Shape -What to Expect

2016年2月26日 Even though approximate, these curves are of great value in crushing-plant design, ... selection of a 3.5″ open- side discharge setting has been made for a standard gyratory primary crusher to be used for crushing quarry-run limestone. ... Any other size of product may be estimated in a similar manner.

More

Tips for designing an efficient crushing and screening operation - Quarry

2013年4月4日 There are several considerations in designing an efficient crushing and screening plant. The first is the raw materials to be crushed. The quarry shot material should be analysed for maximum feed size, gradation, chemical composition, amount of clay, hardness and variations within the deposit or ledges. A list of product sizes needs to be determined as well

More

Plant Design and Configuration - Quarry

Having looked at the various individual components – crushers and crushing; feeders and screens; washing, dewatering, silt/slimes treatments; and conveyors. This PDP will assemble those components into a complete plant.

More

Crushing Optimizing the Process - 911 Metallurgist

–Crushing stage –Crushing plant –Quarry Process • Today: –Optimize the feed ... Optimization of a Final Crushing Stage • Particle Size Distribution Plots • If taking single samples on each CSS the risk of getting inconsistent results might make the graph look strange. 0,67 40

More

Selecting the right type of crushing equipment - Quarry

2016年4月7日 A pit-portable primary crusher can be an economically sound solution in cases where the producer is crushing at the quarry face. In modern plants, ... The maximum feed size varies with each model but is generally limited to 609mm (24”) to 914mm (36”).

More

Quarry Crusher Plant - Complete Stone Crusher Plant and

Quarry Crusher Plant, Find Details and Price about Complete Stone Crusher Plant Crusher Crushing Plant from Quarry Crusher Plant - Shanghai Kinglink Industry Co., Ltd. ... Outlet Size. 150-300mm. Inlet Size. 1000×1200mm. Condition. New. Warranty. 12 Months. Delivery Time. 35working Days.

More

Types of Rock Crushers Quarry Crushing Equipment Kemper

As the first stage in a crushing circuit following extraction from a mine site, (or in the case of recycled asphalt production, delivery to the RAP processing plant via truck transport), primary crushing reduces material to a size and shape that can be handled by the secondary crusher.

More

Castle Quarry Crushing Plant Hire Ltd - Irish Company Info

Castle Quarry Crushing Plant Hire Limited was set up on Tuesday the 28th of September 2010. Their current partial address is Galway, and the company status is Normal. The company's current director has been the director of 4 other Irish companies; 2 of which are now closed. Castle Quarry Crushing Plant Hire Limited has 2 shareholders.

More

Crushing Plant Mining Quarry Plant

South Africa 200 tph granite crushing line, you can get flowchart and price from us. Capacity : 200 tph Feeding sizes : max 700mm Output size : 0-10-20-30mm Equipment : ZSW1300X4900+PE750X1060+HST250+3YZS2160+sand

More

Quarry Crusher Plant for Sale - Shunzhi Mining

5tph Quarry Crushing Plant Price: $6,700 – $7,800: 20tph Quarry Crushing Plant Price: $9,500 – $11,000: 50tph Quarry Crushing Plant Price: $58,000 – $70,000: 80tph Quarry Crushing Plant Price: $65,000 – $76,000: 100tph

More

Limestone Crusher for Efficient Limestone Crushing Plant

Typical limestone crushing plant feature successive size reduction stages and intermediate screening to classify material. A standard flow involves primary, secondary, and tertiary (or fines) crushing. Primary Crushing. Primary crushing, the initial size reduction stage, accepts run-of-mine limestone boulders/cobbles directly from quarry faces.

More

Enhanced plant design for aggregate processing - Quarry

2012年5月1日 The intention of this article is to provide an overview of matters to be considered when designing a crushing and screening plant, starting with a blank sheet – when planning a plant upgrade or extension, pre-existing factors may overrule the ability to incorporate some or all of these considerations.. It is not intended to recommend specific types or brands of machines

More

BASIC CEMENT PLANT LAYOUT – Process Cement Forum - The

2020年7月4日 00 Limestone Quarry and Crushing Plant The major raw material for cement production is limestone. The limestone most suitable for cement production must have some ingredients in specified quantities i.e., calcium carbonates, silica, alumina, iron, etc. Typically, cement plant locations are based upon the availability of good quality limestone in the vicinity.

More

quarry crushing plant- HAMAC

Consultar quarry crushing plant. The quarry crushing plant is a robust and efficient solution for processing large quantities of raw materials. ... The maximum stone size before crushing. From this data, the feed opening of jaw crusher can be confirmed; 2.

More

Quarry - Hodge Plant

2021年10月20日 The quarry was established in 2009, ... Our crushing equipment consists of jaw and cone crushers ... who carry extensive spare parts for plant and equipment operated. News Updates. 28/10/2024; NEW TF-10 Spreadpoint sold and out the door! 09/10/2024; New CASE CX130E sold to JPS Utilities Ltd!

More

SIZE REDUCTION BY CRUSHING METHODS - ResearchGate

2017年3月4日 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the ...

More

How to Start the Business of Stone Crushing - Entrepreneur India

How to Start the Business of Stone Crushing. How to Start the Business of Stone Crushing . Stone crushing plant consists of vibrating feeder, jaw crusher, cone crusher, impact crusher, vibrating screen, belt conveyor and electric control panel

MoreArticle aléatoire

- plan de production de concassage de pierre mobile Tjapan

- béton mobiles de concassage vsi location victoria

- moulin de broyage de feldspath marteau au Pakistan

- de puissance disposition generalegalets

- broyeurs a boulets broyeurs a boulets vente

- processus et équipement miniers

- shanghigh équipement de concassage

- concasseur de carrière de bentonite en arizona

- agregats de plus en plus de concassage

- concassage de pierres et classification de chine

- ce qu est un système de concassage du minerai

- collecteur de poussiere de moulin

- engrais dolomitique à vendre

- équipement D Extraction De Basalte De Broyeur De Basalte Utilisé

- main utilisee concasseur vente mobiles

- leiloao de moinhos de

- broyeurs à marteaux à vendre à tenn

- usine de concassage de roches indonésie

- lettre de ne pas pouvoir assister a une formation

- pierre machine de concasseur fabriquer en Maroc

- les prix de machine a chantier pour

- pièce de rechange des coûts concasseur à cône inde

- portable tambour en verre concasseur

- broyage de billes fait maison

- Concasseur à cne mobile en inde

- Pierre Usine De Concasseur A Himachal En Vente

- pierres formation de l'opérateur concasseur

- pengoprasian la fraiseuse

- broyage des conseils de sécurité de la Sénégal

- charbon specifiions de concasseurs à mâchoires

- plan d affaires concasseur de carrière de granit en italie

- exploitation minière de concasseurs hydrauliques

- concasseur mobile en namibie charbon de russie

- données de production de concasseur canica vsi

- petit equipement minier concasseur à pierre

- vsi concasseur principe de fonctionnement nigeria

- Usine de concasseur de pierres de 100 tonnes

- Comment Vendre Concasseur A Machoires