vertical impact concret crushers

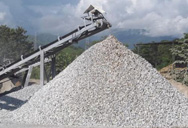

VERTICAL SHAFT IMPACT CRUSHERS

Vertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or quarternary stage crushing. The crushers are suitable for a wide range of applications.

More

Vertical Shaft Impactors - Astec

The efficient and versatile design of the Astec vertical shaft impactors (VSI) delivers highly consistent end products for jobs that demand precision. Astec VSI crushers are available in

More

Trio® TV Series Vertical Shaft Impact (VSI) Crushers Weir

The Trio® TV Series vertical shaft impact crusher is versatile and flexible, containing a range of crushing chamber and different rotor configurations to suit rock on rock (ROR), rock on steel

More

SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT CRUSHERS (VSI)

Sandvik VSI impact crushers are used for production of high-quality manufactured sand and premium shaped aggregates. Other application areas include rolled compressed concrete

More

Our Range of Trio® Vertical Shaft Impactor Crushers

Vertical Shaft Impactors (VSI) are frequently used in mining, aggregate and quarry applications where the particle shape is critical (E.g. concrete, sand, stone and gravel). These high-speed crushers are best suited to secondary, tertiary

More

Vertical Shaft Impact Crushers – G Model– MEKA

Vertical Shaft Impact Crusher (MVI-G) Series is specifically designed for shaping the material after a cone crusher. Rock on rock designation means a few and inexpensive wear parts compared to other alternatives. Adjustable speed and

More

PORTABLE VERTICAL IMPACT (VSI) CRUSHERS WITH

Portable Vertical Impact (VSI) Crushers With Screen. The efficient and versatile design of MEKA portable vertical shaft impactor plants deliver highly-consistent end products for jobs that demand precision. Combining the MVI series VSI

More

CV217 VSI crusher - SRP

Sandvik CV217 VSI impact crusher is designed for tertiary and quaternary applications. CV217. Features. Product data. Request a quote. Features. Reduced operational cost per tonne, maximizing your return on investment.

More

Valor® Vertical Shaft Impactor (VSI) - Superior Industries

Produce Uniform, Road-Building Material. Compared to compression crushers (jaws and cones), impact crushers – like the Valor Vertical Shaft Impactor (VSI) – process a wider range of material at higher tonnages and allow for more

More

CrusherJaw crusherImpact crusherCone

LM Vertical Grinding Mill. Combining numerous functions ensures a more dependable and stable production process, resulting in superior capacity. LUM Ultrafine Vertical Grinding Mill. In contrast to typical grinding mills, this

More

Input and Output Sizes of Vertical Shaft Impact Crusher

The VSI crusher’s efficiency in size reduction is a result of its unique crushing mechanism, which involves rock-on-rock or rock-on-steel impact. This method not only produces a variety of output sizes but also ensures a cubical shape, which is highly desirable in many applications, particularly in the production of concrete and asphalt.

More

MVSI-1000 Portable Vertical Shaft Impact Crusher FABO

Vertical shaft crusher is the crusher with the highest rate in 0-5 mm ... Vibrating Screen separates the products broken in the vertical shaft impact crusher at the desired size and sends them to ... screening plants and concrete plants sector by dominating all regions of the world. CONTACT US. 7 Eylül Mahallesi 5536 Sokak No:4 Torbalı ...

More

Impact Crusher for Concrete Senya Crushers

Looking for high-quality impact crushers for concrete applications? Explore our selection of concrete feeders and screens for your crushing needs. Setup Service Videos (919) 323-4830 ... VSI Series Vertical Impact Crusher.

More

Vertical Shaft Impact Crushers:A Comprehensive Guide

2024年9月4日 Vertical Shaft Impact Crushers Working Principle . Materials enter the VSI Crusher via the feed hopper and are divided into two parts by the distributor. One part is fed directly into the highspeed rotating impeller where it gains acceleration several hundred times that of

More

Vertical Shaft Impact Crusher - hybcrusher

Vertical Shaft Impact Crusher is the most advanced impact crusher in modern world. Hydraulic system used in upper cap, it is easy and convenient to maintenance and replace spare parts. The feeding is our sole patent that using central feeding and central feeding with cascade feeding, the feeding method can change as per needed so as to satisfy customer's different request.

More

Should I Choose an Impact Rock Crusher or Cone Crusher?

Compression crushers include jaw crushers, cone crushers, gyratory crushers and roll crushers. Impact crushers include vertical shaft impactors or horizontal shaft impactors. Compression crushers require much less maintenance; high impact crushers undergo more wear and tear due to the material colliding within the crusher.

More

Vertical Shaft Impact Crusher VSI-800 - Fabo Company

Vertical Shaft Impact Crushers are used in a wide range like from concrete production to asphalt production.VSI 800 Vertical Shaft Impact Crusher have high ratio of sand and cubic. It produces 0.5mm sand and gravel by breaking all kinds of medium size hard material.

More

SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT CRUSHERS

Sandvik VSI impact crushers are used for production of high-quality manufactured sand and premium shaped aggregates. Other application areas include rolled compressed concrete (RCC) for dam construction, recycling industries crushing a range of materials (concrete, glass, slag, etc.) and industrial minerals plants, crushing extremely abrasive high-

More

Impact Crusher - Senya Crushers

Impact crushers (e.g., hammer mills and impact mills) employ sharp blows applied at high speed to free-falling rocks where comminution Save and Make More $$$ Call Today ! (919) 323-4830

More

Home Isc Vsi

Impact Service Corporation® (ISC®) specializes in Vertical Shaft Impact (VSI) Crushers and we have developed the most efficient and durable VSI on the market today. ISC® currently manufactures nine model sizes with a wide

More

How does an impact crusher work? - RUBBLE MASTER

Impact crushers (impactors) reduce mineral materials such as concrete, asphalt, and rock in size producing a cuboid product. Learn how impact crushers work. Skip to content Products Products. Products Mobile Impact ...

More

VERTICAL SHAFT IMPACT CRUSHERS

• Recycling of asphalt and unreinforced concrete waste. ROS Application Feed Material: Basalt, Gravel, Limestone, Dolomite Feed Size: 5-25 mm (4M-1”) VERTICAL SHAFT IMPACT CRUSHERS (VSI) 0% 10% 20% 30% 40% 50% 60% ... VERTICAL SHAFT IMPACT CRUSHERS (VSI) MEKA CRUSHING SCREENING AND CONCRETE BATCHING

More

Our Range of Trio® Vertical Shaft Impactor Crushers Weir

Engineered to produce high-quality, well-shaped particles and fine aggregates, our range of Trio® vertical shaft impactors (or "vertical impact crushers") use innovative technology to deliver outstanding performance in secondary, tertiary and quaternary crushing applications. The enhanced versatility of the Trio® TV Series vertical shaft impactor means that it can handle

More

VERTICAL SHAFT IMPACTOR – PROPEL INDUSTRIES

VERTICAL SHAFT IMPACTOR AVVI SERIES. Propel Vertical Shaft Impactor has been developed with inputs from aggregate producers. The high velocity impact crusher in Propel VSI enhances the shape of the aggregates and improves the surface structure. It is suitable for all types of materials.

More

Modeling of Vertical Shaft Impact Crushers

While most crushers used in the primary and secondary stages of crushing work by having two surfaces compress particles between them, a vertical shaft impact (VSI) crusher instead relies on impact energy. By having the rock particles flung against each other at high rates of speed, the resulting impact creates a high

More

All You Need to Know About: Vertical Shaft Impactor (VSI) Primers

All You Need to Know About: Vertical Shaft Impactor (VSI) Primers By Eric Marcotte, Inside Sales Manager, Stedman Machine Company Vertical Shaft Impactor What Is VSI? All roads, you might say, lead to the Vertical Shaft Impactor (VSI) because these crushers make it possible to create roadways and just about everything else. Francis E. Agnew of California patented one

More

(PDF) INVESTIGATION OF ROCK AGGREGATE QUALITY

2021年12月3日 Concerning cone and vertical shaft impact crushers, ... Typical strength concrete is being made from various aggregates and their impact on various characteristics to the subsequent concrete.

More

Impact Crushers - Powerscreen

They’re also extremely suitable for secondary applications where material is fed by a primary crusher and reduced to a finer product. Powerscreen's impactor range is ideal for shaping applications including making chips, sand, concrete manufacture, and glass recycling. The range includes both horizontal and vertical impact crushers.

More

What is an Impact Crusher?

Although Impact Crushers generally have a higher operating cost than other crushers, they tend to produce a more uniform particle shape (cubical) which is desirable and produce more fines for hot asphalt producers. Common types of Impact Crushers are Horizontal Shaft Impactor (HSI) and Vertical Shaft Impactor (VSI).

MoreArticle aléatoire

- Usines de lavage d or 50tph d occasion à vendre usa

- brun lenox 42 x 32 concasseur machoires vendre

- broyeurs sur une base de location en inde

- degré la température de séchage pour le sable de silice

- carrière minière calcaire

- photo de détail de la cellule de flottation d or

- concasseur a machoires 88 fuxin road

- carrière occasion concasseur de pierre en Afrique du Sud

- usure de la silice sur l installation de concassage

- broyeur a glace 200wkhushkhera

- Crushing equipment 15 tph Spain

- prix de l'usine de concasseur en arabie saoudite

- de concassage broyeur à béton

- machine de concasseur ceramique

- Kumba formation de l'usine de minerai de fer coordonnées

- broyeur à boulets humide sur broyeur à boulets humide

- comment faire du ciment cpj 45

- minerai de fer grumeleux paroles de concasseurs

- concasseur mobile de minerai d or à vendre

- concasseur de pierre 1084

- energy u minerals group bruce walter

- calcite concasseur détails

- Arbres Verticaux Des Moulins à Vent

- Broyeurs Revêtement

- Concasseur De Pierre Portable à Vendre Chine

- petits concasseurs à vendre en usa de l exploitation minière

- equipamentos mineração estrada

- propriétaire de la mine de broyage de balle wiki

- Broyeur concasseur minéral de cône de machines pour la pierre dure

- Meilleur prix broyeur boulets vend

- plan d affaires concasseur de carrière de granit en italie

- exploitation minière de concasseurs hydrauliques

- concasseur mobile en namibie charbon de russie

- données de production de concasseur canica vsi

- petit equipement minier concasseur à pierre

- vsi concasseur principe de fonctionnement nigeria

- Usine de concasseur de pierres de 100 tonnes

- Comment Vendre Concasseur A Machoires