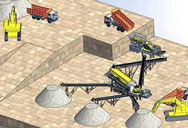

process flow chart for iron ore beneficiation plant

Iron ore beneficiation: an overview - ScienceDirect

2023年1月1日 This chapter briefly discusses the current scenario of the following: iron ore resources in India, iron ore mining methodology, beneficiation techniques for various ore

More

Beneficiation of Iron Ore - 911Metallurgist

2016年5月24日 The Iron Ore Process Flowsheet. The iron ore beneficiation flowsheet presented is typical of the large tonnage magnetic taconite operations. Multi-parallel circuits

More

Beneficiation Plants and Pelletizing Plants for Utilizing Low Grade ...

1. Iron ore - supply and demand outline. 1.1 Types of iron ore. Iron ores can be classified in different ways. The most important has to do with the iron content. In many cases, ore with a

More

SGS MINERALS SERVICES – T3 SGS 960 11-2009

THE FLOTATION PROCESS A standard flotation circuit starts by separating the scrubbed ore into a coarse (for example +20 mesh) and fine (-20 mesh) portions. To design optimum

More

Iron Ore Beneficiation Process Flowsheet PDF

This document provides a flow diagram of a mineral processing plant. It shows the process flow from receiving the raw ore feed hopper through various crushing, grinding, and flotation circuits to produce concentrate products. Key

More

BENEFICIATION OF IRON ORE - National Institute of Technology,

silica in iron ore leading to slime generation which are disposed of in tailing ponds. Slime in these tailing ponds contains iron values in the range of 45-60%. Appropriate beneficiation process

More

World leader in fine iron ore beneficiation - Mineral Technologies

Our process engineers begin with exploring and interrogating fine iron ore beneficiation solutions utilising testwork programs specifically designed to maximise the extraction of

More

Iron Ore Beneficiation Tata Steel Flow Chart

iron ore beneficiation concentration flow chart. flow chart of steel beneficiation plant mine flow chart iron ore beneficiation process Main Slag Processing Flow Chart Main Slag Processing Flow Because the metal concentration is usually quite low in Live Chat; High Concentration 10TPH Tantalite Ore Beneficiation Flow

More

Flow chart of the mineral processing of hematite

Download scientific diagram Flow chart of the mineral processing of hematite iron ore. from publication: An intelligent factory-wide optimal operation system for continuous production process ...

More

process flow chart for iron ore beneficiation plant

Characterization and Beneficiation of Dry Iron Ore process flow schemes were developed and compared with each other to understand the importance of advance separation tech-niques over conventional one for improving the recovery of sinter/pellet grade iron ore concentrate with less than 2.5% alu-mina from rejected iron ore fines of Khondbond ...

More

Executive Summary of - Maharashtra Pollution Control Board

Liberated Iron ore Gangues Plant as Raw Flow chart for Iron Ore Beneficiation Sponge Iron manufacturing Process The process of sponge iron manufacturing involves removal of oxygen from iron ore. Sponge Iron also called as Direct-Reduced Iron (DRI) is produced from direct reduction of iron ore (in

More

iron ore beneficiation plant procedure pdf – Grinding Mill China

2012年12月21日 Iron ore beneficiation plant – Mining, crushing, grinding, Mining . Iron Ore Beneficiation Process: In the Iron ore dressing process, we can adopt ore washing, Iron ore beneficiation plant; View more PDF >> Popular Products; » Free online chat! beneficiation of iron oreiron ore beneficiation flowsheetiron . Beneficiation Equipment The procedure of

More

iron ore beneficiation plant process flow chart

Gulin Least News. iron ore beneficiation plant process flow chart » The More » gold mines for sale zimbabwe » well labelled diagram of vertical raw mill machine » difference between sponge iron and pellets » copper exploration in northern wisconsin » process equipment design book +pdf Contact Us. Tel: 86-21-58386256; Office Add: Pudong New Area, Shanghai, China.

More

Iron Ore Beneficiation Concentration Flow Chart

Iron Ore Beneficiation Process Flow Chart For Processing Plant Iron ore beneficiation process flow chart might be the very best actual Gold ore concentration plant; Get Price. beneficiation concentration .

More

FLOW CHART FOR MINERAL BENEFICIATION PROCESS

Process Flow Chart A process flow chart is a graphical representation of the successive steps involved in a process using symbols interconnected with lines. In case of mineral beneficiation, it is the diagrammatic illustration of various steps involved in the up-gradation of ores/minerals starting from their transportation till their final production to be used as raw materials in

More

Process flow diagram of pelletization unit - ResearchGate

Download scientific diagram Process flow diagram of pelletization unit from publication: Techno-economic Evaluation of Iron Ore Pellet Manufacturing Processes in India and Justification for new ...

More

Iron ore beneficiation Commodities - Mineral

Need iron ore beneficiation expertise? ... The team at Mineral Technologies is continually developing new equipment designs and process flow adaptations to maximise concentrate grades and recovery of iron minerals. ... our

More

Exploring Low-Grade Iron Ore Beneficiation Techniques: A

2024年8月2日 The beneficiation of low-grade iron ores is a key research and development topic in the mineral processing industry. The gradual exhaustion of high-grade iron ore reserves, and rising consumer iron and steel demand globally necessitate efficient low-quality iron ore beneficiation to meet steelmaking quality requirements. This comprehensive review explores

More

Flow chart of the mineral processing of hematite

Download scientific diagram Flow chart of the mineral processing of hematite iron ore. from publication: An intelligent factory-wide optimal operation system for continuous production process ...

More

SGS MINERALS SERVICES – T3 SGS 960 11-2009

BENEFICIATION SGS MINERALS SERVICES’ EXPERTISE WITH BENEFICIATION Beneficiation is the process where ore is reduced in size and gange separated from the ore. Since all iron ore deposits have unique mineralogy, the beneficiation process is specific to each deposit. Separation of certain minerals can be efficiently achieved by taking advantage

More

Process optimization of a chrome ore gravity concentration plant

conventional chromite ore beneficiation process plant (Figure 3) consist of two sections: Communition (for preparing the material for the subsequent unit operations) Concentration (classification and beneficiation). The beneficiation process flow sheet varies from location to location according to the ore characteristics.

More

Iron Ore Processing, General - SpringerLink

2022年10月20日 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill.. Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic deposits with hardness of

More

Iron Ore Beneficiation Plant Equipment For Mining Process

2023年9月4日 Iron Ore Beneficiation Plant Equipment For Mining Process. ... The grinding classification process for iron ore generally adopts two-stage grinding ... According to your situation and requirements, we will design a complete mining production line flow chart and provide an accurate quotation. [email protected] +86-13879771862.

More

Iron Ore Pelletizing Process: An Overview IntechOpen

2018年7月11日 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low-grade iron ore has been processed. The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking. This chapter

More

Iron Ore Pelletizing Process: An Overview - ResearchGate

PDF On Jul 11, 2018, Sandra Lúcia de Moraes and others published Iron Ore Pelletizing Process: An Overview Find, read and cite all the research you need on ResearchGate

More

Direct Reduced Iron and its Production Processes – IspatGuru

2013年3月16日 Major DRI production processes are either natural gas based or coal based. Feed material for the DR process is either sized iron ore of size ranging from 10 mm to 30 mm or iron ore pellets of size ranging from 8 mm to 20 mm produced in an iron ore pellet plant. The gas based process uses a shaft furnace for the reduction reaction.

MoreArticle aléatoire

- molino de molienda conica

- fabricant de concasseur de roche aux ÉtatsUnis

- broyeur à percussion pour s à singapour

- centre de traitement de l or broyeur à boulets avec la rondelle

- utilisé jumbo concasseur sélection de

- results le prix du Quartz de cuivre

- haut fourneau usine de broyage de scories

- Disposition du broyeur à jet à lit fluidisé

- trouver concasseurs à percussion occasion

- concasseur mobile priy minerai de chromite à vendre

- ma2015 britador de mandíbulas

- Minéral De Flottation Minéral

- principaux Fournisseurs de concasseurs de pierres en chine

- gardera des broyeurs

- Séparateur de fer de laitier en acier

- 113 concasseur à percussion

- entreprise de vente de crucher en pierre au kenya

- original jaw broyeur for sale

- bebe moulin broyeur d broyeur

- machine de fabrication du savon en algrie

- results fait la machine de flottation en or

- usine de lavage d or au ghana émirats arabes unis concasseur

- concasseurs portables à cône melbourne

- machines de revêtement époxy

- enrichissement pour le minerai de wollastonite

- vente pierre de limpôt sur Formet concasseurs

- extension pour concasseurs de pierres dans l andhra pradesh

- inventaire gardner denver

- silicium poreux broyage

- optimisation de l usine de concassage de leur efficacite

- plan d affaires concasseur de carrière de granit en italie

- exploitation minière de concasseurs hydrauliques

- concasseur mobile en namibie charbon de russie

- données de production de concasseur canica vsi

- petit equipement minier concasseur à pierre

- vsi concasseur principe de fonctionnement nigeria

- Usine de concasseur de pierres de 100 tonnes

- Comment Vendre Concasseur A Machoires